Mining Conveyor Transport Efficiency

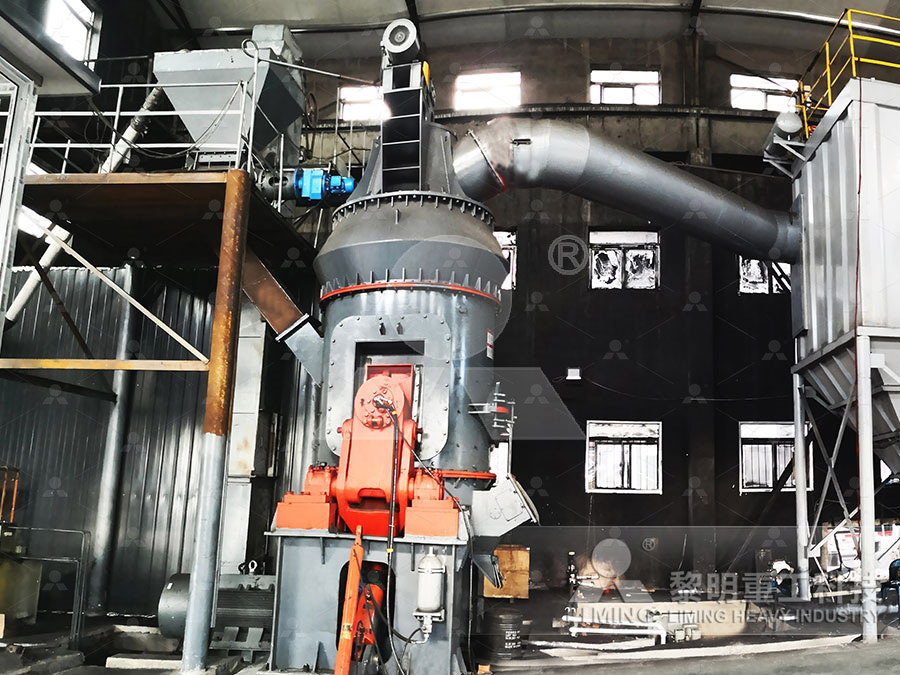

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)51.jpg)

Study of the efficiency of conveyors of mining transport

The task of building an energyefficient transport system is reduced to justify the scheme of transportation of rock mass from the faces to the bunker, the calculation of freight flows, the choice of means of transport with the maximum possible efficiency, the2020年1月1日 — Various electric drive systems that can be used on conveyors are compared We have studied the relative inclination that affects the efficiency of conveyors, as well Study of the efficiency of conveyors of mining transport 2016年1月1日 — Abstract This paper substantiates application of pit conveyors at the stages of pit rework and underground mining beyondedge reserves Heavy pit lift transport is Increasing the Work Scope of Conveyor Transport at Mining 2020年10月13日 — The key issue in an energyefficient transportation system is reducing the value of specific energy consumption (SEC) by increasing conveyor capacity whilst decreasing belt conveyor motion(PDF) Specific Energy Consumption of a Belt

An Effective Belt Conveyor for Underground Ore Transportation Systems

2017年12月1日 — As the key elements of a belt conveyor, the energyefficient conveyor belt and optimised carrying idlers have been developed for the new generation of 2024年5月28日 — The conveyor belt in mining industry plays a vital role in streamlining transportation processes, enhancing efficiency, and boosting productivity in mining operations Initially introduced in the early 20th Innovative Conveyor Belt for Mining Industry 2024年6月2日 — This ensures efficient and safe transport of materials on steep slopes Load Capacity: The load capacity of the belt must match the volume and weight of the materials being transported Heavyduty belts Essential Types of Conveyor Belts Used in Mining2024年3月14日 — The critical role of mining conveyor equipment in the efficient movement of materials is evident in both openpit and underground mining operations: OpenPit Mining: In openpit mining, belt conveyors Innovations in Mining Conveyor Equipment

.jpg)

Conveyor screw systems – A guide to maximising efficiency

3 天之前 — A conveyor screw is a versatile, efficient bulk material handling system Understand components and applications to unlock the full potential Mining Conveyor Explosives; Additives and Processing Chemicals; Menu For example, the food industry can use screw conveyors to transport powdery and granular food products, while waste 2024年5月28日 — What is the use of conveyor belt in mining? Conveyor belts are a vital component in mining operations, facilitating the continuous and efficient transport of materials In mining, conveyor belts are used to move extracted minerals, such as coal, ore, and other raw materials, from the mining site to processing facilities or loading areasConveyor Belt in Underground Mining: Key SelectionDOI: 1015587/172940612019 Corpus ID: ; Improving energy efficiency of coal transportation by adjusting the speeds of a combine and a mine face conveyor @article{Stadnik2019ImprovingEE, title={Improving energy efficiency of coal transportation by adjusting the speeds of a combine and a mine face conveyor}, author={Mykola Improving energy efficiency of coal transportation by 2024年6月5日 — Conveyor belts play a critical role in coal mining operations, serving as an essential component in the transportation of coal A coal mine conveyor belt is designed to efficiently move large quantities of coal from the mining site to processing facilities, reducing the need for manual labor and enhancing overall operational efficiencyCoal Mine Conveyor Belt Systems Choose and Purpose

.jpg)

TruckandLoader Versus Conveyor Belt System: An

2019年2月22日 — The oscillation of the main mining commodities prices and the significant increase in the operating costs has forced this sector to look into processes that are more and more efficient The transportation costs in an openpit mine operation can account forExplore the world of conveyor belt with Eka Conveyors, addressing efficiency and solutions in material handling Skip to content Choosing the right conveyor belt is crucial for the efficient and reliable transportation of materials in mining operations The mining industry has specific requirements that influence the selection process Mining Conveyor Belt Selection: Key Factors to ConsiderMining Belt Conveyors are vital components in the mining industry, enabling efficient transportation of materials over long distances and challenging terrains To meet the diverse needs of mining operations, various types of conveyor belts have been developed In this blog, we will delve into the four main types of conveyor belts used in mining: steel cord Mining Belt Conveyors: Exploring the Key Conveyor Belt Types2023年9月5日 — Aggregate conveyor systems, often called "conveyors," are integral to material handling systems They are designed to transport bulk materials, such as aggregates, gravel, sand, or even heavyduty Intro to Aggregate Equipment: Aggregate

.jpg)

Reducing the energy consumption of the conveyor transport

2019年6月1日 — The article deals with the actual issue of reducing the energy consumption of the mining enterprises conveyor transport system The analysis of energy loss by conveyor belt during transportation of bulk load is given A comparative analysis of energy losses in the cases of regulation and nonregulation of the speed of the conveyor belt is 3 天之前 — Mining and minerals processing In the mining industry, these type of conveyors transport minerals and ores, such as coal, limestone, phosphate, and more They play a critical role in bulk material handling Bucket elevators: A comprehensive guide2022年4月22日 — Analysis of belt transportation systems only in Polish brown coal mines shows the scale of the problem The “Belchatow” lignite mine, which extracts above 4 × 10 7 Mg of coal and more than 1 × 10 8 m 3 of overlay per year, may be a good example here The transportation of materials in the “Belchatow” mine is performed with the use of belt Energy Efficiency of Conveyor Belts in Raw Materials Industry Advantages of Mining Conveyor Belt 1 Increased Efficiency Conveyor belts in mining and quarrying operations improve material handling efficiency This, in turn, enables higher production rates It also reduces downtime associated with manual labour or truck transportation Conveyor belts facilitate uninterrupted material flowMining Conveyor Belt for Handling Heavy Industry

Boosting Mining Efficiency Lies Within Conveyor Belts in Mining

2023年7月19日 — Conveyor belts have transformed the mining and quarrying industry by providing efficient and safe material transportation solutions From material extraction and stockpiling to processing and haulage, conveyor belts have become indispensable tools for enhancing productivity, reducing costs, and improving worker safety2023年8月17日 — Further, remote mine sites can often mean weeks of waiting on a repair or replacement component, making reliability a top priority Conveyor reliability is dependent upon a number of factors Most notably the following: Build quality – Mineduty conveyors require heavyduty components and rugged materials of construction This might also Essential considerations in belt conveyor design Canadian Mining 2024年9月23日 — Mining conveyor belts are specialized types of conveyor belts that find application in the mining industry for transporting various mining products such as ore, coal, and slag These conveyor belts are engineered to be highly durable, resistant to wear and corrosion, and ensure the safe and efficient transportation of materials from mining Everything You Need Know about Mining Conveyor Belts2024年5月24日 — The conveyor system’s efficiency in moving these materials supports the productivity and growth of these sectors, further diversifying Oklahoma’s industrial base 5 Environmental Benefits While coal mining and transport have environmental impacts, the conveyor belt system helps mitigate some of these effectsWorld’s Longest Conveyor Belts

Choosing A Conveyor Belt Used in Mining

2024年6月2日 — How Thick Is a Mining Conveyor Belt? The thickness of a mining conveyor belt varies depending on the type of belt and its intended use Generally, mining conveyor belts range from 5mm to 20mm in thickness Factors influencing belt thickness include the material being transported, the required tensile strength, and the environmental conditions2021年8月10日 — A conveyor system is a type of mechanical handling equipment that is used to transfer material from one place to anotherConveyors provide ease of use in applications such as the What is Conveyor System? Types, Parts, 2023年8月29日 — Conveyor belts have transformed the mining and quarrying industry by providing efficient and safe material transportation solutions From material extraction and stockpiling to processing and Conveyor Belts in Mining and Quarrying: 2021年3月31日 — distributed into the multi conveyor drive of the mining industry that can result in efficient mining production capacity and transport distances [7] The multi conveyor drives have appeared as convenient for reducing drive system weights and achieving high performance [16] ToANALYSIS OF CONVEYOR DRIVE POWER

Underground Mining Conveyor Belt System

2024年3月18日 — The underground mining conveyor belt is not just a transport mechanism but a critical infrastructure component that enhances the safety, efficiency, and environmental sustainability of underground mining operations Understanding the key features of these belts can provide insight into their indispensable role in the mining 2024年5月15日 — Conveyor belt systems play a crucial role in material transport within mining operations, and any leakage or spillage of hazardous substances from the conveyor can result in water contamination To prevent this, underground conveyor belts are designed with leakproof seals and containment systems to prevent the escape of fluids and Optimizing Underground Conveyor Belt Operations2024年3月14日 — Underground Coal Mining Conveyor Belts in Thermal Power Plants The role of an underground coal mining conveyor belt extends beyond the confines of the mine itself, playing a pivotal role in the operation of thermal power plants These conveyor systems are critical for the continuous, efficient, and safe supply of coal to power Innovations in Underground Coal Mining Conveyor Belt 2024年3月19日 — Coal handling plays a pivotal role in the efficiency and sustainability of various industries, most notably in thermal power plants and coal mining operations belt conveyor system for coal handling transport large volumes of coal over long distances efficiently, reducing operational costsThe process of moving coal from point A to point B Belt Conveyor System for Coal Handling in a Thermal Power

Study of the efficiency of conveyors of mining transport

2020年1月1日 — The article examines the efficiency of belt conveyors in mining transport systems mining complexes Various electric drive systems that can be used on conveyors are compared2021年12月17日 — Interests: mining engineering; mining; conveyor transport in mines; mining machines; mining technologies; designs and calculations for haulage and hoist Results of tests into the energyefficiency of belt conveyor transportation systems indicate that the energy consumption of their drive mechanisms can be limited by lowering the main EnergyEfficiency of Conveyor Belts in Raw Materials IndustryThe most environmentally friendly type of open mine transport is conveyor transport [3] In addition, the advantage of conveyor transport in comparison with other types is the ability to fully automate the control of its work, which causes a minimum number of staff At the same time, the operator is in a safe place with a goodImproving the efficiency of conveyor transport with the 2021年2月1日 — As a crucial element in coal transportation, conveyor belts play a vital role, and monitoring their health is essential for the coal mine transportation system’s safe and efficient operationDeep learningbased damage detection of mining conveyor

.jpg)

Simulation Study on Dynamic Characteristics of

2023年12月12日 — The longwall fully mechanized mining technology is presently the most efficient and extensively employed technique in coal mining The shearer, hydraulic support, and scraper conveyor are the Mining conveyor systems are getting larger, more durable and going underground storage locations with belt conveyors and conveying equipment have a great influence on the efficiency of the entire transport Mining conveyor systems ABB conveyor 2024年9月24日 — Mining conveyor belt systems enable the movement of material from one point to another in openpit and underground mining operations Conveyors are used to transport ores, concentrates and Mining Conveyor Belt Manufacturers, Systems and Solutions 2024年5月11日 — Conveyor belts are integral to the mining industry, playing a critical role in the efficient and continuous transport of materials from extraction points to processing locations or transport systems These belts help in moving a vast range of materials, including ores and minerals, over varying distances and terrainsMastering Material Transport: A Guide to Conveyor Belts in Mining

.jpg)

How Conveyor Belts are Transforming Mining:

2023年8月15日 — Introduction The mining industry has witnessed significant technological advancements over the years, with Conveyor Belt playing a pivotal role in transforming the way materials are transported 2023年3月30日 — speed plays a decisive role in the transportation of materials, but excessive rotation speed will reduce the transportation efficiency of materials When the rotating speed of the blades of the screw conveyor increases, the time it takes for the screw conveyor to convey the same batch of materials is shorter, butAnalysis of Coal Transportation Efficiency of Horizontal 2020年12月9日 — This article presents the analysis of conveyor drive power requirements for three typical mining conveyors One of the conveyors was found not to be able to start when fully loadedAnalysis of Conveyor Drive Power Requirements in the Mining 2024年3月15日 — Continuous material transportation in the mining industry through conveyor belts is widely efficient However, the varying conditions of force and operation make these belts susceptible to tears, misalignments, and damages, hampering production Longitudinal tears, in particular, pose problems due to their potential for accidents and belt breaksEfficient monitoring of longitudinal tears in conveyor belts

Energy Efficiency of Conveyor Belts in Raw Materials Industry

2022年4月22日 — The development of conveyor belt transport systems, as well as system process management, is increasing efficiency levels Mining transport is a complex process, requiring large amounts of energy 2024年5月28日 — The conveyor belt in mining industry plays a vital role in streamlining transportation processes, enhancing efficiency, and boosting productivity in mining operations Initially introduced in the early 20th Innovative Conveyor Belt for Mining Industry 2024年6月2日 — This ensures efficient and safe transport of materials on steep slopes Load Capacity: The load capacity of the belt must match the volume and weight of the materials being transported Heavyduty belts Essential Types of Conveyor Belts Used in Mining2024年3月14日 — The critical role of mining conveyor equipment in the efficient movement of materials is evident in both openpit and underground mining operations: OpenPit Mining: In openpit mining, belt conveyors Innovations in Mining Conveyor Equipment

.jpg)

Conveyor screw systems – A guide to maximising efficiency

3 天之前 — A conveyor screw is a versatile, efficient bulk material handling system Understand components and applications to unlock the full potential Mining Conveyor Explosives; Additives and Processing Chemicals; Menu For example, the food industry can use screw conveyors to transport powdery and granular food products, while waste 2024年5月28日 — What is the use of conveyor belt in mining? Conveyor belts are a vital component in mining operations, facilitating the continuous and efficient transport of materials In mining, conveyor belts are used to move extracted minerals, such as coal, ore, and other raw materials, from the mining site to processing facilities or loading areasConveyor Belt in Underground Mining: Key SelectionDOI: 1015587/172940612019 Corpus ID: ; Improving energy efficiency of coal transportation by adjusting the speeds of a combine and a mine face conveyor @article{Stadnik2019ImprovingEE, title={Improving energy efficiency of coal transportation by adjusting the speeds of a combine and a mine face conveyor}, author={Mykola Improving energy efficiency of coal transportation by 2024年6月5日 — Conveyor belts play a critical role in coal mining operations, serving as an essential component in the transportation of coal A coal mine conveyor belt is designed to efficiently move large quantities of coal from the mining site to processing facilities, reducing the need for manual labor and enhancing overall operational efficiencyCoal Mine Conveyor Belt Systems Choose and Purpose

.jpg)

TruckandLoader Versus Conveyor Belt System: An

2019年2月22日 — The oscillation of the main mining commodities prices and the significant increase in the operating costs has forced this sector to look into processes that are more and more efficient The transportation costs in an openpit mine operation can account forExplore the world of conveyor belt with Eka Conveyors, addressing efficiency and solutions in material handling Skip to content Choosing the right conveyor belt is crucial for the efficient and reliable transportation of materials in mining operations The mining industry has specific requirements that influence the selection process Mining Conveyor Belt Selection: Key Factors to ConsiderMining Belt Conveyors are vital components in the mining industry, enabling efficient transportation of materials over long distances and challenging terrains To meet the diverse needs of mining operations, various types of conveyor belts have been developed In this blog, we will delve into the four main types of conveyor belts used in mining: steel cord Mining Belt Conveyors: Exploring the Key Conveyor Belt Types