Ball Charge In Ball Mills What Is

Ball Mill an overview ScienceDirect Topics

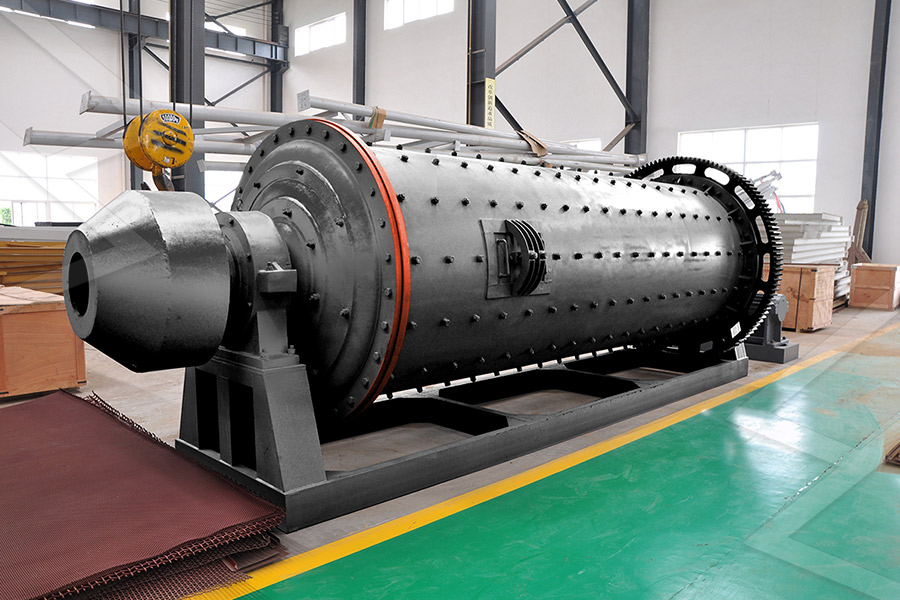

The normal charge of balls is about 5 Mg/m 3 In small mills where very fine grinding is required, pebbles are often used in place of balls In the compound mill, the cylinder is divided into a number of compartments by vertical perforated platesReactive ball milling Reactive ball milling method is to mill starting materials under Ball Milling2021年3月12日 — Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can BALL MILLS Ball mill optimisation Holzinger ConsultingBall charge optimization : Purpose: Optimization of a ball charge for cement and raw mills with objective of optimizing the grinding efficiency Best Practice: The ball charge in first Ball charge optimization INFINITY FOR CEMENT EQUIPMENT

Ball Mill an overview ScienceDirect Topics

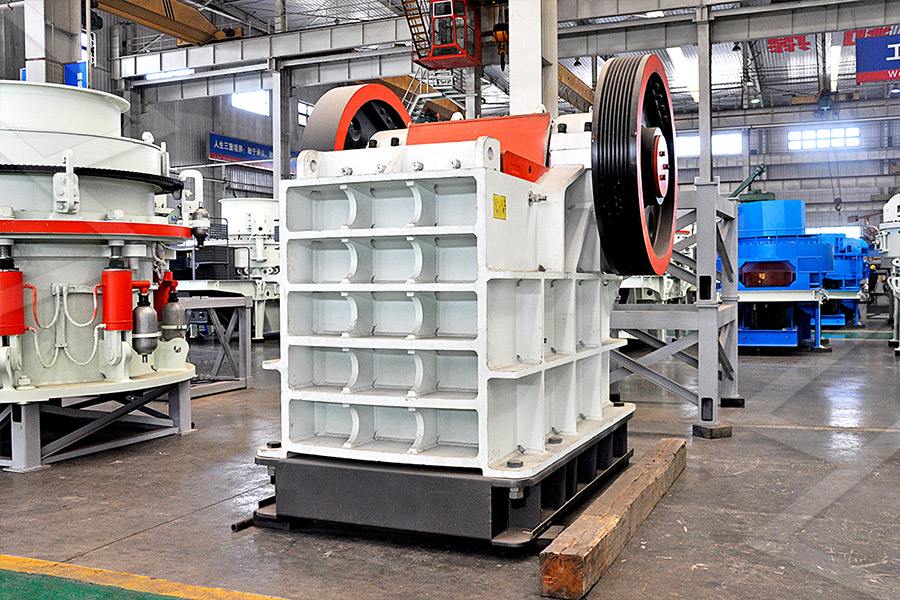

Ball mills give a controlled final grind and produce flotation feed of a uniform size Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but 2001年8月1日 — Discrete element method (DEM) modelling has been used to systematically study the effects of changes in mill operating parameters and particle properties on the Charge behaviour and power consumption in ball mills: Usually, an SAG mill is charged to 30–35% of its interior volume The grinding balls occupy 5–15% of the volume [10] The charge volume can be estimated by measuring the Mill Charge an overview ScienceDirect Topics2020年7月2日 — In recent research done by AmanNejad and Barani [93] using DEM to investigate the effect of ball size distribution on ball milling, charging the mill speed with (PDF) Effects of Ball Size Distribution and Mill Speed and

.jpg)

Ball Charge in Ball Mill PDF Mill (Grinding)

2019年12月2日 — The document discusses how ball mill filling degree impacts specific power consumption and mill capacity Lowering the ball mill filling percentage negatively affects mill sizing and increases capital 2022年2月10日 — The document discusses ball charge management in ball mill systems It addresses the need to top up the ball charge as balls wear down over time to maintain grinding efficiency and production levels The Ball Charge Management PDF Mill (Grinding)Pelletizing plant of the GolEGohar mining and industrial company consists of a burner, a dry ball mill (62 m × 13 m), and an air separator The ball mill consists of a 2 mlong drying and an 11 ExpandSimulation of ball charge motion in ball mills Semantic 2024年5月27日 — Ball mills are widely used in the beneficiation process for various ores and minerals, including gold, copper, iron, and zinc The TITAN design enables you to run a full process load with a 40% ball Ball Mills in the Mineral Processing Industry

Guidelines for sample amount and ball charge Content

2023年3月24日 — Ball charge Mixer Mill MM 500 nano/ control Please be aware that the maximum allowed ball size may vary, depending on the jar material! The MM 500 nano is perfect for wet grinding and mechanochemistry The MM 500 control is suitable for dry, wet grinding and cryogenic grinding withAutogenous and SemiAutogenous Mills In Mineral Processing Design and Operations (Second Edition), 2016 933 M ill Charge Usually, an SAG mill is charged to 30–35% of its interior volume The grinding balls occupy 5–15% of the volume [10]The charge volume can be estimated by measuring the distance between the top level of the charge and the Mill Charge an overview ScienceDirect TopicsFor overflow ball mills, the charge should not exceed 45% of the mill volume For grate discharge mills, the charge should occupy about 50% of the mill volume Bond developed a relationship that can be used to determine the percent charge by volume as a function of the vertical height above the charge, He, and the radius of the mill, R, ie, AMIT 135: Lesson 7 Ball Mills CircuitsBall mill A typical type of fine grinder is the ball mill A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls Ball mills normally operate with an approximate ball charge of 30%What is the difference between a SAG mill and ball mill?

.jpg)

17 Signs of Problems with Ball Mills: Quickly Remove Hidden Troubles

2023年2月15日 — High temperature of the ball mill will affact the efficiency 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% 10% 4 when the moisture is greater than 5%, the ball mill will be unable to perform the grinding operation 5 The bearing of the ball mill is overheated and the motor is overloaded ReasonsDOI: 101016/03017516(92)900769 Corpus ID: ; Optimization of the makeup ball charge in a grinding mill @article{Concha1992OptimizationOT, title={Optimization of the makeup ball charge in a grinding mill}, author={Fernando Concha and L Magne and Leonard G Austin}, journal={International Journal of Mineral Processing}, year={1992}, Optimization of the makeup ball charge in a grinding millWhen charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product Charging a Dry Mill The general operation of a grinding mill is to have the product impacted between the balls as they tumble If there are Ball Mill Loading Dry Milling Paul O AbbeThe ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral Crosssection of typical ball mills showing various charge

.jpg)

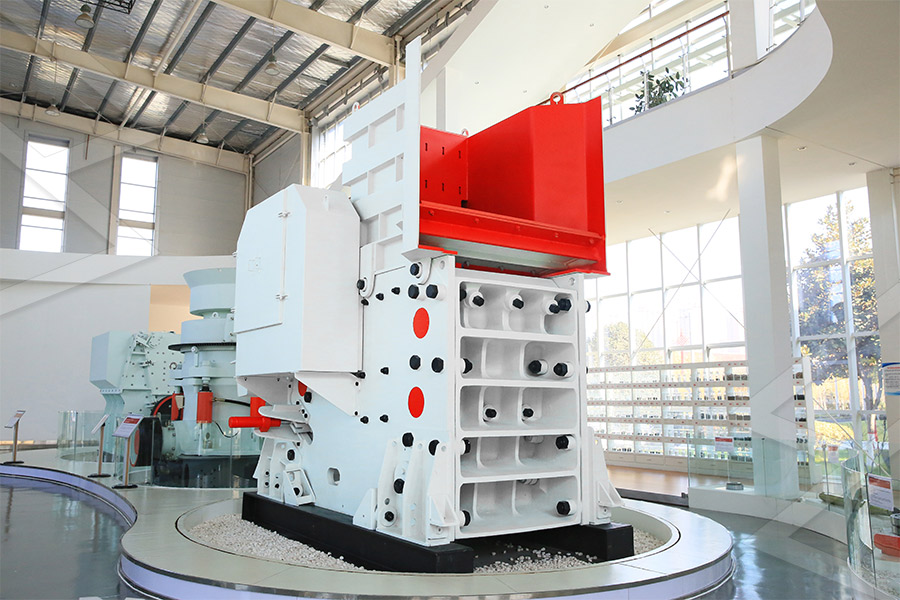

Ball charge optimization INFINITY FOR CEMENT EQUIPMENT

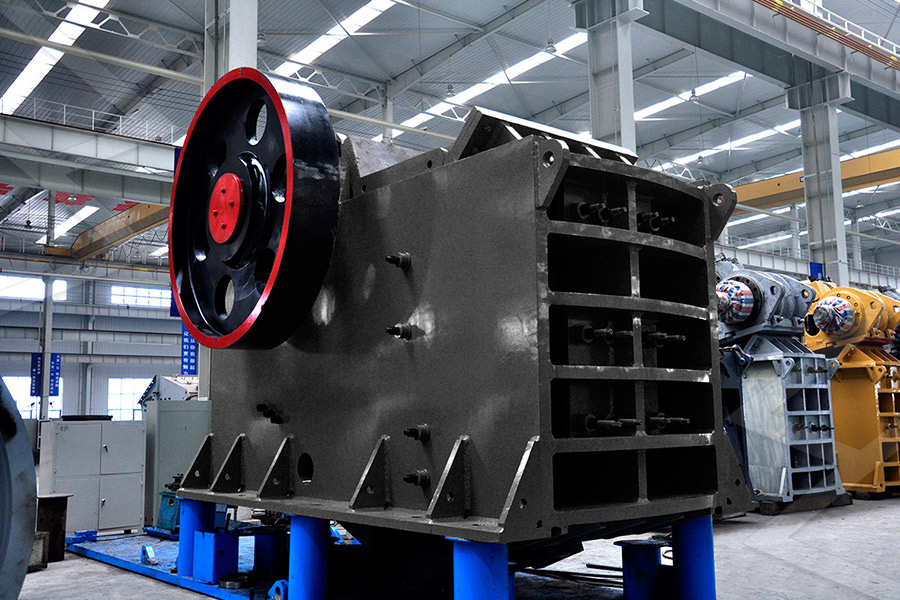

The raw mill will be operate with a much coarser ball charge than the cement mill mainly because of the bigger slot sizes of the partition wall The transition zone consists of 50 mm and 60 mm balls The basis is a 50 mm ball size for 5% residue on the 4 mm sieve In case bigger grains are bypassing the partition through the center grate even Ball Mill Introduction There are three main stages to mineral processing in the mining industryThese are: Comminution (crushing and grinding); Beneficiation (separation and concentration); Smelting and refining; Ball Ball Mill (Ball Mills Explained) saVRee saVRee2018年7月24日 — Ball top size (bond formula): calculation of the top size grinding media (balls or cylpebs):Modification of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and Ball charges calculators2024年8月8日 — Ball Mill Success: A StepbyStep Guide to Choosing the Right Grinding Media {{lastDate}} Introduction In the intricate dance of ball milling, where raw materials are transformed into finely milled particles, the choice of grinding media emerges as a pivotal performance lever This seemingly minor selection can dramatically influence the Ball Mill Success: A StepbyStep Guide to Choosing the

.jpg)

(PDF) Grinding Media in Ball MillsA Review ResearchGate

2023年4月23日 — One of the most used tumbling mills is the ball mill This paper reviews different types of grinding media that have been developed and improved over the years and their propertiesThe Planetary Ball Mill PM 300 is a powerful and ergonomic benchtop model with two grinding stations for grinding jar volumes up to 500 ml For most reactions, the 1:2 speed ratio of jar to sun wheel of the models PM 100 and PM 200 is fully adequate, as the ball charge produces enough impact energy However, greater energy is required for Planetary Ball Mill PM 300 RETSCH laboratory equipment2023年2月15日 — A beneficiation plant in Singapore loads balls into a ϕ 1500mm×3000mm wet grid type ball mill, determines the filling rate ϕ = 50%, and selects cast steel grinding balls δ = 45 t/m 3 The ball mill processes the mediumhard ore 1 See Table 1 for the sieving analysis results of all the ore samples from a ball mill Table 1Method of Steel Grinding Ball Proportioning and Example2015年12月14日 — Place Material Charge and Ball Charge in Mill Run x revolutions x = number of revolutions based on estimate of work index; usually 50, 100, 150 or 200 revolutions Dump Mill, separate balls and Material Charge Screen all the material at Mesh of Grind – Weigh Product Product = weight of Material Charge – weight of Screen Standard Bond Ball Mill Grindability Test MethodProcedure

.jpg)

Optimization of the makeup ball charge in a grinding

2023年7月30日 — The ball charge in the mill is split into L ball classes with diameters in a 4x/2 ratio, and mt is the relative mass frequency function of balls of size dr It is found that an appropriate mean 2015年6月19日 — The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum Ball Mill Design/Power Calculation 911Metallurgist2024年9月22日 — 1 Ball Size Distribution in Ball Mills: The ball size distribution in a ball mill refers to the range of ball sizes used in the mill It is typically represented as a cumulative percentage of the total ball charge The optimal ball size distribution ensures maximum contact area between the balls, leading to efficient grindingBall size distribution in ball mills: Optimization and impact on 2015年6月19日 — We can calculate the steel charge volume of a ball or rod mill and express it as the % of the volume within the liners that is filled with grinding media While the mill is stopped, the charge volume can be Mill Steel Charge Volume Calculation

.jpg)

Optimization of the makeup ball charge in a

1992年3月1日 — The mills were unloaded and the ball charge was screened in order to establish the ball size distribution For both mills, the balls retained during the unloading were compared to the balls 2016年4月22日 — Data on ball charges for BallRod Mills are listed in Table 5 Further information regarding grinding balls is included in Table 6 What is the Steel Charge of a Ball Mill Difference Between a Rod Mill and Ball Mill Rod Mills has a very define and narrow discharge product size range Feeding a Rod Mill finer rocks will greatly impact its Ball Mill Rod Mill Design 911Metallurgist2022年2月10日 — Ball Charge Management Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online The document discusses ball charge management in ball mill systems It addresses the need to top up the ball charge as balls wear down over time to maintain grinding efficiency and production Ball Charge Management PDF Mill (Grinding) Nature1995年1月1日 — This paper focuses on the use of a numerical tool known as the discrete element method (DEM) to study the motion of ball charge in ball mills DEM is employed to simulate the motion of individual (PDF) Ball Charge Dynamics in a Planetary Mill ResearchGate

(PDF) Effects of Ball Size Distribution and Mill Speed and

2020年7月2日 — When the mill charge contained monosized balls, the ball flow regime inside the mill transited to the cataracting and impact breakage was the main breakage mechanism Increasing the fraction of Ball Charge Ball mills for cement grinding usually operate with a filling degree between 25 and 35 % The filling degree is defined as the volume of the grinding media (balls) as a percentage of the total mill volume Since mill speed, liner shape and mill diameter are usually unchangeable parameters, the only adjustment in a mill can be made Process Training Ball Mill INFINITY FOR CEMENT EQUIPMENTmation used to date to describe size reduction in mills DEM makes it possible to predict how collisions vary in magnitude and frequency as the geometry, the ball charge and the mill speed are varied Therefore, instead of correlating each individual parameter such as mill diameter, filling, speed and ball size, for instance, to the productA Review of Advanced Ball Mill Modelling JSTAGE2017年5月8日 — values of ball charge, however, a correction factor is necessary and this has been determined by experiment and is given in Fig 312 In the use of this factor the power is calculated on the basis that the mill has a ball charge equal to that in the actual overflow mill and the normal correction for powder charge is introducedGrinding Mill Power 911Metallurgist

Experimental study of charge dynamics in a laboratoryscale ball mill

To understand and describe the behavior of charge dynamics in mills, a series of dry and wet grinding tests were performed on a laboratoryscale ball mill The comparisons between experimental results and grinding media trajectory simulations were addressed Results show that the grinding media trajectory simulations exhibit a good agreement with the 1993年5月1日 — This paper focuses on the use of a numerical tool known as the discrete element method (DEM) to study the motion of ball charge in ball mills DEM is employed to simulate the motion of individual balls While doing so, the effect of liner design on the grinding performance of the mill is studied Two important factors, such as the Numerical simulation of charge motion in ball mills Springer2023年6月28日 — ball charging grinding media handling automatic safe sorting and handling of grinding media in the range 27mm to 150mm diameter 2 from delivery to mills ball storage winner innovation excellence award 2012 winner cy o'connor award for excellence in engineering technology 2012 transminauBALL CHARGING GRINDING MEDIA HANDLINGThe mills were unloaded and the ball charge was screened in order to Expand 3 PDF Save Modeling on the Effect of Coal Loads on Kinetic Energy of Balls for Ball Mills Yan Bai Fangwei He Engineering 2015; This paper presents a solution for the detection and control of coal loads that is more accurate and convenient than those Exploring ball size distribution in coal grinding mills

how to calculate ball charge in ball mill Knowledge

2024年4月22日 — To calculate the ball charge in a ball mill, you need to consider the following factors: The volume of the mill: Measure the internal volume of the mill This can be done by filling the mill with balls and material then measuring the total volume The percentage of the mill volume occupied by the media: Typically, the ball charge occupies 1994年2月1日 — The friction between the ball charge and the mill shell can increase the power draft The center of the ball mass shifts in distance as much as 4% of the mill diameter during a complete rotation Finally, the distribution of collision energy and the spatial locations of high and lowenergy collisions are shown While many of the Simulation of charge motion in ball mills Part 2: numerical 2016年6月6日 — These mills typically grind ROM ore in a single stage A large example of such a mill was converted from a singlestage milling application to a semi autogenous ballmillcrushing circuit, and the application is well described This refers to highaspect AG/SAG mills Ball Charge Motion inside a SAG Mill With a higher density mill chargeSAG Mill Grinding Circuit Design 911Metallurgist2017年7月3日 — New feed entering at one end of the mill causes the rod charge to spread at that end This produces a series of wedge shaped slots tapering toward the discharge end The voids (or interstitial space) within a rod load are approximately half those in a ball mill grinding load Rods in place weigh approximately 400 pounds per cu ft and Ball Mills vs Rod Mills 911Metallurgist

Charge behaviour and power consumption in ball mills:

2001年8月1日 — Discrete element method (DEM) modelling has been used to systematically study the effects of changes in mill operating parameters and particle properties on the charge shape and power draw of a 5 2023年10月2日 — Control of the total charge and the ball charge volume is vital to the optimum performance of semiautogenous grinding (SAG) mills to maximise throughput and energy efficiency(PDF) RealTime Estimation of SAG Mill ChargePelletizing plant of the GolEGohar mining and industrial company consists of a burner, a dry ball mill (62 m × 13 m), and an air separator The ball mill consists of a 2 mlong drying and an 11 ExpandSimulation of ball charge motion in ball mills Semantic 2024年5月27日 — Ball mills are widely used in the beneficiation process for various ores and minerals, including gold, copper, iron, and zinc The TITAN design enables you to run a full process load with a 40% ball Ball Mills in the Mineral Processing Industry

Guidelines for sample amount and ball charge Content

2023年3月24日 — Ball charge Mixer Mill MM 500 nano/ control Please be aware that the maximum allowed ball size may vary, depending on the jar material! The MM 500 nano is perfect for wet grinding and mechanochemistry The MM 500 control is suitable for dry, wet grinding and cryogenic grinding withAutogenous and SemiAutogenous Mills In Mineral Processing Design and Operations (Second Edition), 2016 933 M ill Charge Usually, an SAG mill is charged to 30–35% of its interior volume The grinding balls occupy 5–15% of the volume [10]The charge volume can be estimated by measuring the distance between the top level of the charge and the Mill Charge an overview ScienceDirect TopicsFor overflow ball mills, the charge should not exceed 45% of the mill volume For grate discharge mills, the charge should occupy about 50% of the mill volume Bond developed a relationship that can be used to determine the percent charge by volume as a function of the vertical height above the charge, He, and the radius of the mill, R, ie, AMIT 135: Lesson 7 Ball Mills CircuitsBall mill A typical type of fine grinder is the ball mill A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls Ball mills normally operate with an approximate ball charge of 30%What is the difference between a SAG mill and ball mill?

17 Signs of Problems with Ball Mills: Quickly Remove Hidden Troubles

2023年2月15日 — High temperature of the ball mill will affact the efficiency 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% 10% 4 when the moisture is greater than 5%, the ball mill will be unable to perform the grinding operation 5 The bearing of the ball mill is overheated and the motor is overloaded ReasonsDOI: 101016/03017516(92)900769 Corpus ID: ; Optimization of the makeup ball charge in a grinding mill @article{Concha1992OptimizationOT, title={Optimization of the makeup ball charge in a grinding mill}, author={Fernando Concha and L Magne and Leonard G Austin}, journal={International Journal of Mineral Processing}, year={1992}, Optimization of the makeup ball charge in a grinding millWhen charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product Charging a Dry Mill The general operation of a grinding mill is to have the product impacted between the balls as they tumble If there are Ball Mill Loading Dry Milling Paul O AbbeThe ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral Crosssection of typical ball mills showing various charge