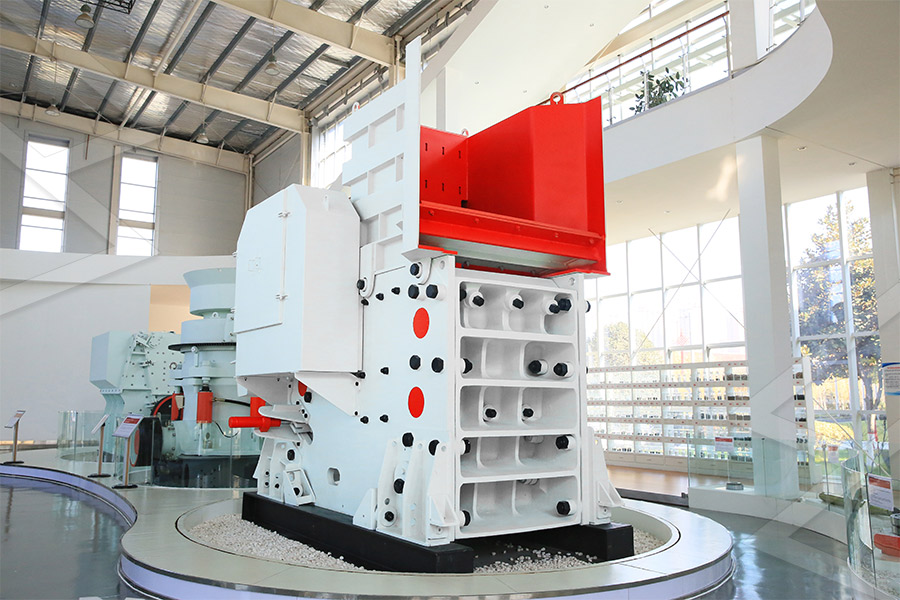

Great Wall Mining Processing Jaw Crusher

.jpg)

Stone Crusher,Cone Crusher,Jaw Crusher,Mobile Crushing

2023年8月8日 — Great Wall Company offers stone crushers and grinding mill for mineral quarrying,crushing,dressing,High Quality Trustworthy SupplierE Stone crushing plant mainly includes vibrating feeder, jaw crusher, cone Stone Crushing Plant2024年6月25日 — PE jaw crusher is a highproductivity crusher independently produced by GreatWallMachinery, which is mainly used for crushing all kinds of materials with PE Jaw CrusherStone Crusher MachineHenan Greatwall 2023年10月12日 — Stone crushing plant mainly includes vibrating feeder, jaw crusher, cone crusher, impact crusher, vertical shaft impact crusher, vibrating screen, belt conveyor, electric control panel, etc It could crush Stone Crushing Plant,Stone Crushing Plant

JAW CRUSHER Xinxiang Great Wall Machinery

Consult Xinxiang Great Wall Machinery Co, Ltd's JAW CRUSHER brochure on DirectIndustry Page: 1/22023年11月14日 — Jaw crusher is used for crushing all kinds of ores and rocks with compressive strength below 320MPa It is generally used for primary crushing of materials The machine is widely used in mining, pe jaw crusher, jaw crusher price, jaw crusher for 2024年6月25日 — Because of its practical equipment performance, the crawler jaw mobile crushing station is often used for processing materials with high hardness and high Crawler jaw crushing stationMobile Crusher MachineHenan 2024年8月22日 — Great Wall Machinery is a renowned manufacturer in the stone crushing and mineral grinding industry Headquartered in Zhengzhou, China, our expansive factory spans over 120 hectares, empowering us to stone crusher manufacturer,crushing

.jpg)

Stone Crusher Manufacturer, Mineral Crusher, Jaw Crusher

With more than 20 years' history, Zhengzhou Great Wall Heavy Industry Machinery Co, Ltd is a top manufacturer specializing in RD, designing manufacturing and selling Since 2024年7月27日 — There are small jaw crusher, medium jaw crusher and large jaw crusher in crushing plant Great Wall Company will brief introduce you jaw crusher series in Jaw crusher series for sale Great Wall (China Manufacturer) Mining It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc The pressure resistance strength is under 200Mpa, that is, suitable for primary crushjaw crusher 百度百科2024年9月21日 — DOVE Jaw Crushers are ideal rock crusher machines, highly efficient and economical for handling Primary and Secondary stone crushing applications of various ores and bulk materials with Jaw Crusher Crushing Plant Hard Rock Mining

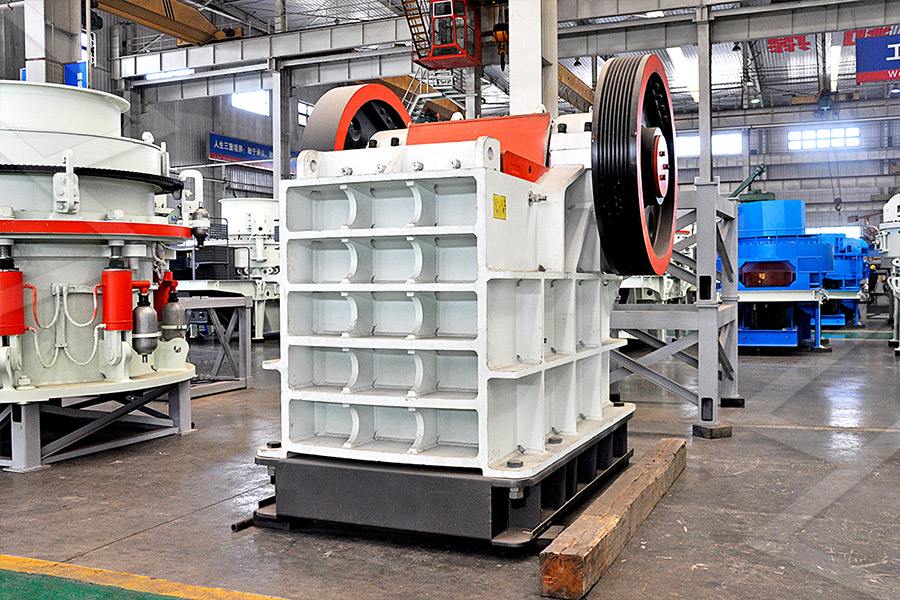

VYKIN 8JC Mobile Mini Tracked Jaw Crusher

5 天之前 — Model: VYKIN 8JC Configuration: Jaw crusher Power System: Direct drive Engine: 14HP gas engine Fuel Consumption: 026 – 052 gal/hr, 158 gal capacity Electrical Control: Yes, wireless remote standard 2024年8月20日 — The jaw crusher has a simple structure, is easy to manufacture, reliable in operation, and convenient to use and maintain The fineness of the jaw crusher can be varied from 10mm to 105mm, and it can be adjusted according to customers' needs Jaw crusher prices vary according to model and production capacityJaw Crusher Basics in 3 MinutesSBM Industrial Technology 2013年4月4日 — Mining Quarry Plant Processing equipment for mineral ore and stone rock for: Home; About Us; Products Import Mini Jaw Crusher directly from China factory, Zhengzhou Great Wall Heavy Industry Machinery Co, Ltd, and enjoy FREE trade assistant service from DHgate Factory miniature jaw crusher Mining Quarry PlantProcess Description Jaw crusher is used in primary crushing for stones and bulk materials It processes various kinds of ore with compression strength not more than 320mp It has been widely applied in area of is widely used in mining, quarry, metallurgy, building, highway, railway, construction wastes processing, water conservancy and cement JAW CRUSHER Xinxiang Great Wall Machinery Co, Ltd

.jpg)

Intro to Aggregate Equipment: The Jaw Crusher

2023年9月5日 — A jaw crusher is a sturdy machine that breaks down big rocks and ores into smaller pieces It has two main parts: a fixed jaw that doesn't move and a swinging jaw that does They are frequently used in rock quarries or by manufacturers that need to break material down until all the pieces are of equal size How Does It Work?2014年4月1日 — Real estate in an underground mine is not cheap, so the design of primary crushing plants has more limitations underground than on the surface which is good for belt conveyors and fits into most secondary crushers without causing process risks To achieve this top size, the crusher setting is 200mm or below, depending on the rock Below the surface: Setting up an underground primary jaw crusherFor example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top ie the opening), and each jaw will have a 54inch width If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimensionJaw Crusher Explained saVRee2023年11月14日 — PE Jaw Crusher Jaw crusher is used for crushing all kinds of ores and rocks with compressive strength below 320MPa It is generally used for primary crushing of materials The machine is widely used in mining, building materials, metallurgy, electric power, water conservancy, transportation and many other fields Tel: 0086371pe jaw crusher, jaw crusher price, jaw crusher for sale, jaw crusher

.jpg)

Types of Crushers Explained: Everything You Need to Know

2024年4月19日 — Atrition crushing is great for the production of very fine particle sizes and it is commonly used in mineral processing and mining for grinding ore A singletoggle jaw crusher is simpler in design and is widely used because of its low cost and ease of maintenance On the one hand, the doubletoggle jaw crushers have a more complicated 2024年2月1日 — Jaw crusher is an important equipment on many production line, There are 4 bearings on the eccentric shaft for jaw crushser: two on each side of the jaw frame supporting the shaft and two at each end of What are the Jaw Crusher Eccentric Shaft 2024年8月29日 — A small jaw crusher is a type of jaw crusher that is specifically designed for smallscale operations, laboratories, or where space and capacity constraints exist These crushers are suitable for crushing small amounts of hard materials into smaller, more manageable pieces Laboratories: For sample preparation and testingSmall Jaw Crusher TAYMACHINERY5 天之前 — How To Use A Jaw Crusher? If you want to use a jaw crusher to crush rocks or other materials, there are a few key things that you should keep in mind First, you will need to carefully select the jaw plates so that Jaw Crusher: What Is It How Does It Work?

.jpg)

Optimisation of the swinging jaw design for a single toggle jaw crusher

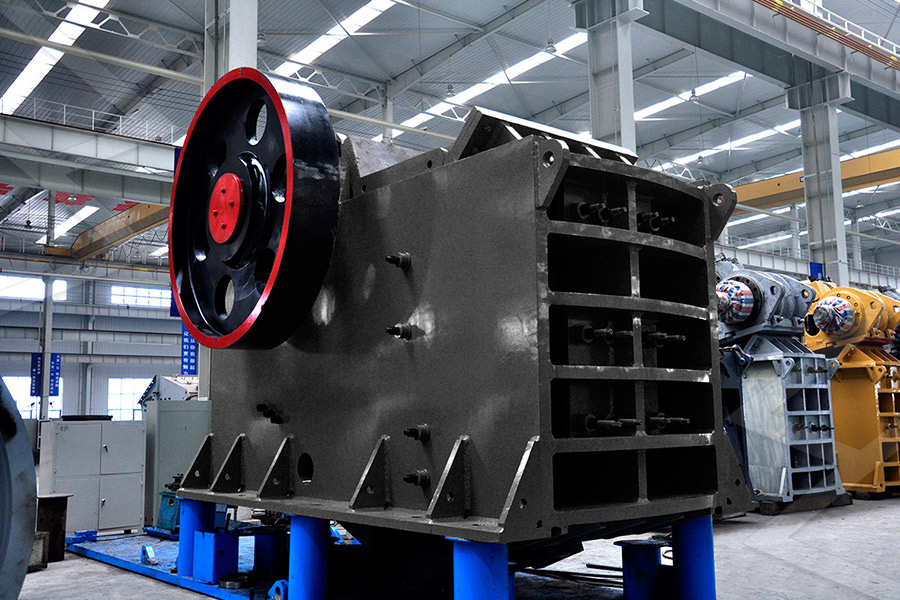

2022年9月20日 — This study reports on the design optimisation of the swinging jaw crusher plate Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing During the crushing process, large and nonevenly distributed impact forces occur, With our Great Wall Brand, we will constantly improve ourselves and try our best to provide perfect products and best services to our clients Cone crusher, Jaw crusher, Mining processing equipment City/Province: Zhengzhou, Henan, China Paper Pulp Making Machine Screening Equipment Vibrating ScreenStone Crusher Manufacturer, Mineral Crusher, Jaw Crusher 2023年8月5日 — Great Wall Heavy Industry mainly produces crushing and grinding equipment, main products include cone crusher, impact crusher, vertical impact crusher, jaw crusher, milling machine, etc We could provide complete sets of stone production line, sand making line, mobile crushing plant and grinding plant for mining, building materials, About Great Wall Great Wall Company greatwallcrusherOften considered a basic machine, jaw crushers have their place in the industry They are often used to reduce rock into nonuniformed gravel To find out more about primary jaw crusher check out our blog Cross section of a Kleeman primary jaw crusher Gyratory crushers Run of mine material is transferred into a gyratory crusher’s upper Types of Crushers: What You Need to Know HUATAO GROUP

Jaw Crushers Manufacturer JXSC

The main difference between a jaw crusher and an impact crusher is the material that it can handle and the processing size of minerals: Jaw crushers process harder rocks like granite, basalt, ores, and concrete Impact crushers work best with semihard materials like clay, limestone, coal, and dolomite2019年11月19日 — How you select the best primary crusher from all of the available primary crushers is required a great deal of design based on the mining plan and operation input Usually, capacity, feed size, product size, rock compressive strength, abrasion index and mobility of crusher are considering as criteria, and in practice usage, gyratory, double How To Select Your Primary Crusher JXSC Mining2024年2月20日 — High Processing Ability: Highcapacity jaw crushers can crush up to 5000 tons of material per hour, making them perfect for largescale mining and quarrying jobs For example, in a largescale copper mine, a jaw crusher plays a crucial role in breaking down huge chunks of ore before they're further processed in grinding millsWhat's the Difference: Impact Crusher vs Jaw Crusher JXSC6 天之前 — The Terminator Jaw Crusher is the ultimate in fine crushing Unmatched for its crushing speed, consistent material reduction and reliability! With actual material fineness of 95% minus 2mm after a single 110 feed pass, the Terminator is designed to last and incorporates unique features setting it apart from its competitorsTerminator Jaw Crusher TM Engineering

Crushing and Screening Handbook AusIMM

2021年6月24日 — preferred supplier in the rock processing industry Our highest priority and personal commitment is to provide lifetime support and service for your aggregates processing operations Whether you need a single crusher, a multistage process or a complete plant, we assist you with the right design for the most costeff ective crushing 2023年2月28日 — Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working The Complete Guide to Primary Crushing, 2024年3月20日 — This shaft makes the movable jaw plate swing back and forth, crushing the material against the fixed jaw plate Depending on the size of the crusher and how hard the material is, a jaw crusher typically uses between 1 and 2 kWh of energy for each ton of material it processesUltimate Comparison: Jaw Crusher vs Cone Crusher JXSCThe moving jaw rotates around the eccentric axis as well as swings around the same center (Fig 2)By removing the moving jaw suspension shaft and the front toggle plate of simple pendulum jaw crusher, and suspending the moving jaw on eccentric shaft to combine the connecting rod and the moving jaw into whole, a compound pendulum jaw crusher takes Jaw Crusher SpringerLink

Jaw crusher EB FLSmidth

For example, the patented swing jaw and front wall design absorb load peaks during operations In our Pro series, we offer the following models (see more details below) Jaw Crusher EB 2015 Pro with a capacity range of 600 – 1,600 tph; Jaw Crusher EB 1612 Pro with a capacity range of 400 – 1,200 tph2023年10月12日 — Stone crushing plant mainly includes vibrating feeder, jaw crusher, cone crusher, impact crusher, vertical shaft impact crusher, vibrating screen, belt conveyor, electric control panel, etc It could crush and screen various materials such as limestone, marble, granite, basalt, river stone, etc to produce sand and gravels for construction with Stone Crushing Plant,Stone Crushing Plant price,Stone Crushing Plant Jaw crushers are the workhorse of the crushing industry for mining, construction, and demolition recycling Mt Baker Mining and Metals’ jaw crushers are industrial grade, continuous duty machines They take large pieces of rock, ore, concrete, or other materials, and crush them down to smaller sizes, for further processing in a ball mill or hammer mill, 16″ x 24″ Jaw Crusher Mt Baker Mining and Metals4 天之前 — The frame of C5X Jaw Crusher is fully welded by adopting the newly deeparc welding process to meet structural and strength requirements After welding, an effective aging treatment process is carried out to reduce or eliminate postwelding stress, and comprehensive testings are conducted to ensure the frame's reliabilityC5X Jaw CrusherSBM Industrial Technology Group

.jpg)

Small Jaw Crusher TAYMACHINERY

5 天之前 — A small jaw crusher is a type of jaw crusher that is specifically designed for smallscale operations, laboratories, or where space and capacity constraints exist These crushers are suitable for crushing small amounts of hard materials into smaller, more manageable pieces Laboratories: For sample preparation and testing2024年2月18日 — A jaw crusher is an indispensable tool in the mining and construction industries, known for its power to fragment hard materials such as rock and minerals Comprising type of jaw crusher—the robust Single Jaw Crusher Diagram: Simplified Guide JXSC2024年2月1日 — Jaw plate is also called toothed plate, which is the key wearresistant part of jaw crusher A set of jaw plate is usually composed of two parts, namely, the moving jaw plate and fixed jaw plate Jaw plate is the major component of jaw crusher, including moving jaw plate and static jaw plate There are different sizes according to the different Introduction to high manganese steel jaw plate of jaw crusherThe working principle of a Cone Crusher is similar to that of a Gyratory Crusher, however, it is usually in use for secondary and tertiary crushing of granite, basalt, gneiss and other hard rock, as well as in the mining and cement industries Such as a Jaw Crusher it works on the basis of compression and squeezes the material until it breaks Crushers Sizers manufactor thyssenkrupp

.jpg)

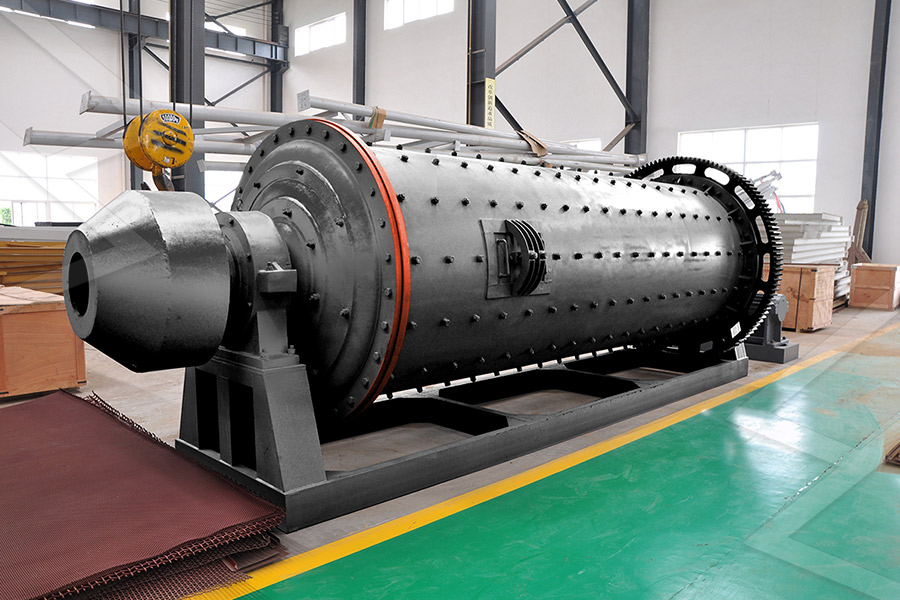

Cone crusher promising prospect in mining industry

2021年12月3日 — Compared with traditional stone crusher such as jaw crusher,roll crusher and impact crusher;cone crusher has high crushing ratio for materials fine granularitythe cone crusher crushes the raw materials into fine and even grained shape,which is not only energysaving,but also can be used for high hardness brittle materialsCone crusher is 2024年2月1日 — Moving Jaw is major component of large jaw crusher It is widely used in the mine industry, chemical engineering, cement industry, steel and iron industry, etc Great Wall Casting carries out the technology improvement and innovation in making the casting parts by summarizing our cast experience The large movable jaw parts designed and Moving Jaw for Crusher greatwallcasting2023年2月21日 — Crushing Process in a Jaw Crusher The crushing process in a jaw crusher begins with the feeding of the material into the crushing chamber The material is crushed between a fixed jaw and a moving jaw, which moves back and forth against the fixed jaw The material is crushed by the compressive force generated by the movement of the two The Ultimate Guide to Jaw Crushing Machines: Types2017年6月2日 — The gap between the two jaws narrows as the material moves through the crusher, further reducing the size Jaw crushers are heavy duty machines and can be used in mining or quarry applications for very hard materials Jaw crusher Mineral sizers are one of the newer technologies to the crushing industry They feature two rotors, each fixed How it Works: Crushers, Grinding Mills and Pulverizers

Jaw Crusher Mineral Crushing Aggregate Processing JXSC Mining

4 天之前 — Application Field Jaw Crusher is widely used to crush materials into medium size in the first crushing process of ore rocks, so your rocks would get be ready for the secondary crushing it had a wide range of suitable materials, such as granite, marble, basalt, limestone, quartz, pebble, iron ore, copper ore and so on the jaw crusher is applicated in 2024年2月1日 — Jaw crusher is a kind of size reduction machine which is widely used in the mining and aggregates industrytween jaw plates and material particles brings the inevitable and serious wear to the jaw plates during the jaw crusher operation, which not only decreases the efficiency, but also increases the cost and the energy consumption of How does jaw plate help stone crusher work?2024年9月18日 — characteristics of the ore, the crusher setting, crusher size and the connected power to the crusher The family of primary crushers typically used in the mining industry include the: • Gyratory • Double toggle jaw • Single toggle jaw • High speed roll crusher • Low speed sizer HISTORYPrimary Crusher Optimisation for Improved 2024年9月21日 — DOVE Jaw Crushers are ideal rock crusher machines, highly efficient and economical for handling Primary and Secondary stone crushing applications of various ores and bulk materials with Jaw Crusher Crushing Plant Hard Rock Mining

.jpg)

VYKIN 8JC Mobile Mini Tracked Jaw Crusher

5 天之前 — Model: VYKIN 8JC Configuration: Jaw crusher Power System: Direct drive Engine: 14HP gas engine Fuel Consumption: 026 – 052 gal/hr, 158 gal capacity Electrical Control: Yes, wireless remote standard 2024年8月20日 — The jaw crusher has a simple structure, is easy to manufacture, reliable in operation, and convenient to use and maintain The fineness of the jaw crusher can be varied from 10mm to 105mm, and it can be adjusted according to customers' needs Jaw crusher prices vary according to model and production capacityJaw Crusher Basics in 3 MinutesSBM Industrial Technology 2013年4月4日 — Mining Quarry Plant Processing equipment for mineral ore and stone rock for: Home; About Us; Products Import Mini Jaw Crusher directly from China factory, Zhengzhou Great Wall Heavy Industry Machinery Co, Ltd, and enjoy FREE trade assistant service from DHgate Factory miniature jaw crusher Mining Quarry PlantProcess Description Jaw crusher is used in primary crushing for stones and bulk materials It processes various kinds of ore with compression strength not more than 320mp It has been widely applied in area of is widely used in mining, quarry, metallurgy, building, highway, railway, construction wastes processing, water conservancy and cement JAW CRUSHER Xinxiang Great Wall Machinery Co, Ltd

.jpg)

Intro to Aggregate Equipment: The Jaw Crusher

2023年9月5日 — A jaw crusher is a sturdy machine that breaks down big rocks and ores into smaller pieces It has two main parts: a fixed jaw that doesn't move and a swinging jaw that does They are frequently used in rock quarries or by manufacturers that need to break material down until all the pieces are of equal size How Does It Work?2014年4月1日 — Real estate in an underground mine is not cheap, so the design of primary crushing plants has more limitations underground than on the surface which is good for belt conveyors and fits into most secondary crushers without causing process risks To achieve this top size, the crusher setting is 200mm or below, depending on the rock Below the surface: Setting up an underground primary jaw crusherFor example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top ie the opening), and each jaw will have a 54inch width If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimensionJaw Crusher Explained saVRee2023年11月14日 — PE Jaw Crusher Jaw crusher is used for crushing all kinds of ores and rocks with compressive strength below 320MPa It is generally used for primary crushing of materials The machine is widely used in mining, building materials, metallurgy, electric power, water conservancy, transportation and many other fields Tel: 0086371pe jaw crusher, jaw crusher price, jaw crusher for sale, jaw crusher

Types of Crushers Explained: Everything You Need to Know

2024年4月19日 — Atrition crushing is great for the production of very fine particle sizes and it is commonly used in mineral processing and mining for grinding ore A singletoggle jaw crusher is simpler in design and is widely used because of its low cost and ease of maintenance On the one hand, the doubletoggle jaw crushers have a more complicated