Mining Mill Plant Mobilaization

.jpg)

Integrating Underground Blast Fragmentation Modeling for

2024年9月1日 — By optimizing underground mine bench blasting practices, mining companies can reduce their environmental footprint, improve operational efficiency, and enhance longterm economic viability The proposed methodology offers a practical 2001年5月27日 — The objective of the Mine to Process Optimization project was to develop integrated mining and processing strategies to increase production and improve the Modelling and Simulation Techniques Applied for Optimisation of Mine 2 天之前 — In 2024, we sold our first complete solution to the mining company, Idwala Carbonates in KwazuluNatal, South Africa, which now has an AI mill optimisation system and an AI machine surveillance system Loesche mills: Now assisted with artificial 1997年5月9日 — The geochemical, mineralogical and geohydrological data can help to develop remedial strategies for arresting the acid mine drainage and the attendant Mobilization and retention of heavy metals in milltailings

(PDF) Mine to Mill Optimisation at Mt Wright ResearchGate

2022年8月22日 — Abstract In 2019, ArcelorMittal Exploitation Minière (AMEM) and Hatch conducted a MinetoMill (M2M) integration and optimisation project at Mont Wright (MW) 2021年4月19日 — Regarding this background, this article describes the feasibility of mine to mill optimization from three aspects: (1) different energy efficiencies between drillingblasting and(PDF) Feasibility and necessity of mine to mill2 天之前 — This paper describes the application of integrated JKSimMet and Limn simulations for MinetoProcess optimisation of two mining operations •The first Multicomponent MinetoMill optimisation applied to iron 2015年8月24日 — The aim of this paper is to show how fragmentation optimisation has yielded positive results at all stages of the production chain, from the mine to the mill OneMine Fragmentation Optimisation – Adopting Mine to Mill

Mining Mill Plant Mobilaization pannakladatel

Mining Mill Plant Mobilaization T02:06:09+00:00 Research articleBlended pulp mill, forest humus and mine 2018年12月15日 In this study, we amended five contrasting 2019年3月1日 — Crawford proposed a complete reconciliation flowscheme where each step of the operation is examined sequentially from model to mine, mine to mill, mill to smelter Proactive reconciliation as a tool for integrating mining and 2018年12月15日 — 1 Introduction Mine tailings, the principal solid residuals generated from metalliferous mining activities (Santibáñez et al, 2008), are prone to high concentrations of heavy metals that are potentially toxic to plants and soil biota (Hue, 1995)Vast volumes of these tailings are disposed on mining sites, and depending on the effluent containment Blended pulp mill, forest humus and mine residual material Mine and Mill Industrial Supply Company was incorporated under the name Mulberry Explosives and Supply Company on Octobr 28, 1909 It began as a supply company for the many sawmills and phosphate mining About Mine Mill

Process integration and optimization from minetomill

2024年8月6日 — Process integration and optimization from minetomill WValery,AJankovic,DLaRosa,ADance,SEsen,JColacioppo Minerals Process Technology AsiaPacific 2024年4月11日 — Location: Mount Zynai Industrial Park, Barangay Santa Cruz, Diplahan, Zamboanga Sibugay, Mindanao, Philippines; Coordinates (): 7, 122 (approximate); Background On June 18, 2022, land preparation for the proposed steel plant began at Mount Zynai Industrial Park in Diplahan town of Zamboanga SibugayMount Zynai Integratred Steel Mill and Smelting Plant2022年8月22日 — Throughout the M2M project, sitespecific models of the mine and plant (blast fragmentation, crushing, grinding, gravity separation) were developed and calibrated based on historical data, and (PDF) Mine to Mill Optimisation at Mt Wright ResearchGate2500 South Combee Road Lakeland, FL 33801 Phone: 8002828489, 8636655601 Fax: 8636671907Home Page [minemill]

Newmont Refractory Plant Mill #6 – Western Mining History

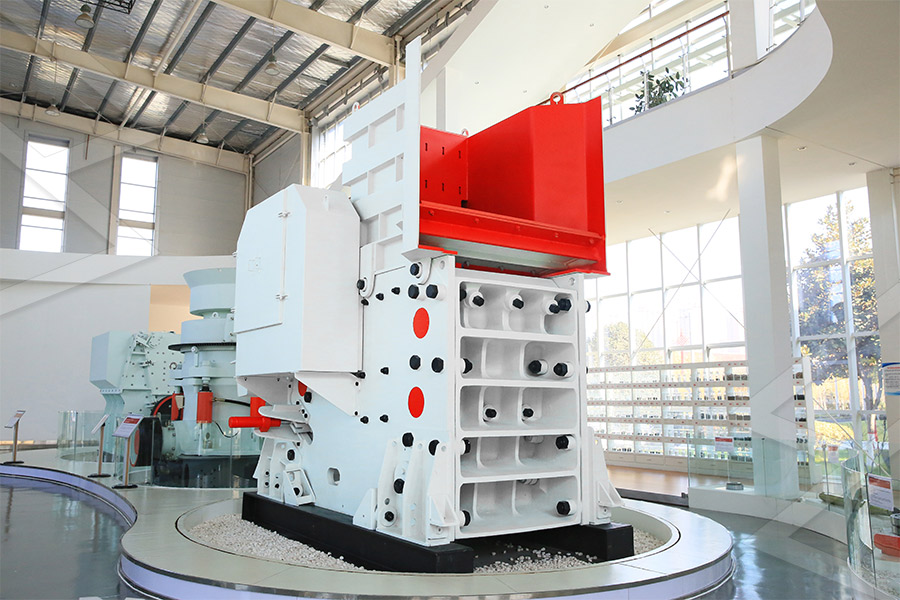

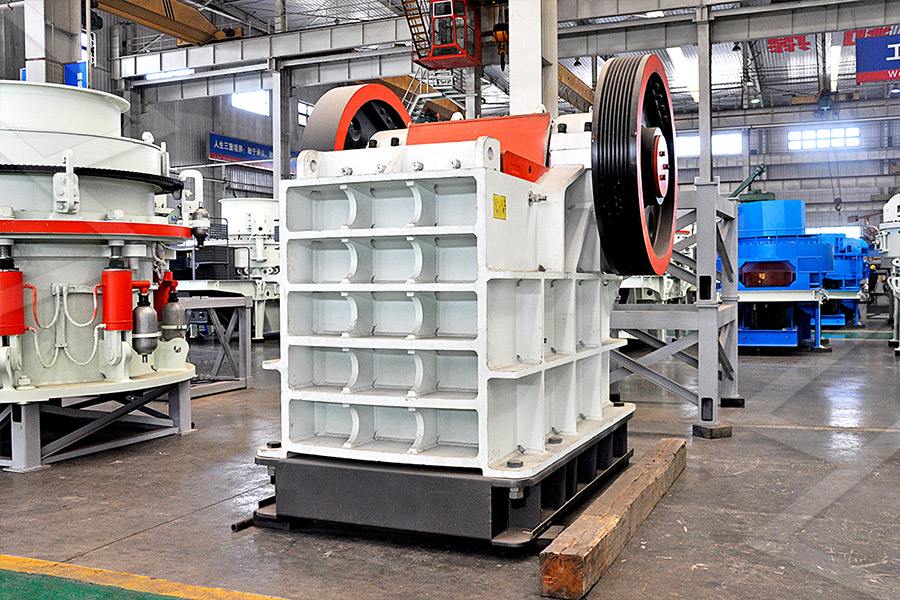

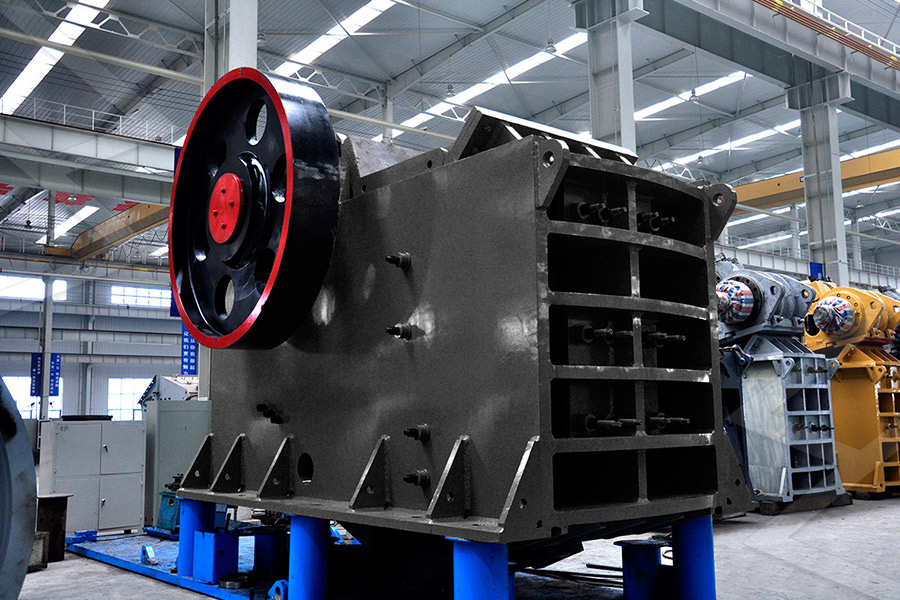

6 天之前 — The Newmont Refractory Plant Mill #6 is a mine located in Eureka county, Nevada at an elevation of 6,562 feet About the MRDS Data: All mine locations were obtained from the USGS Mineral Resources Data System The locations and other information in this database have not been verified for accuracy It should be assumed 2017年6月2日 — Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap How it Works: Crushers, Grinding Mills and Pulverizers2018年11月5日 — Minetomill optimisation is a holistic approach to minimising energy and operating costs in mineral processing by optimising all stages within the size reduction process, explains Motion Metrics mine and plant operators must optimise the particle size distribution for each stage of comminution based on an understanding of how each stage Minetomill optimisation Mining Magazine2015年8月8日 — Batch mills Mills which receive a discrete quantity of charge which is milled and then discharged The process is then repeated Continuous mills A mill which can accept a continuous flow of feedstock and hence can operate on a continuous basis Both batch and continuous mills have their relative merits Peripheral and trunnion dischargeMineral processing milling

USING PROCESS INTEGRATION

2012年9月24日 — The production of minerals for economic use is a twostage process, involving mining to extract the mineral from the ground, and processing to convert the mineral into a marketable product2023年10月10日 — This mine uses several SAG mills as part of its operations to produce over 1 million tonnes of copper annually In addition, there are other notable examples such as Grasberg Mine in Indonesia and Understanding the SAG Mill in Copper Ore 2019年9月22日 — JSC AK Altynalmas engaged Esen Mining Consulting Pty Ltd (EMC) to conduct a drilltomill plant optimization project to determine what opportunities exist to increase the mill throughput and DRILLTOMILL PLANT OPTIMIZATION AT HIGmill high intensity grinding mill is an advanced and energyefficient fine and ultrafine grinding solution that relies on proven technology Mining Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process Stirred mill plants unitsHIGmill high intensity grinding mill

.jpg)

> UNDErsTaNDINg MINE TO MILL Mine to" h="ID=SERP,52282">UNDErsTaNDINg MINE TO MILL 911 Metallurgist

2024年9月20日 — 5 >> UNDErsTaNDINg MINE TO MILL Mine to Mill, which links aspects of mining and mineral processing in order to optimise the combined mining and processing stages, has been under development and use for the last 20 years Implemented effectively, numerous operations have experienced productivity gains from Mine to Mill in the range 2010年8月13日 — factory, mill, plant, works 的区别 这四个词都可表示 “ 工厂 ”,注意以下用法: 1 factory 泛指一般意义的 “ 工厂 ”,是最普通,用得最广泛的一个词。如: a clothing factory 服装厂 a glass factory 玻璃厂 a food factory 食品厂 a paper factory 造纸厂factory, mill, plant, works的区别2024年9月24日 — A project mobilization can be a project in itself, or else it is often the first phase of the project implementation Like any other project, it can be divided into phases like a planning phase and an execution phase in which regular monitoring and controlling help to avoid errors or to correct them in good time if necessaryProject Mobilization Plan for Construction Projects worldofpm2023年8月29日 — and commodity knowledge to the global mining industry Pioneering the concept in the 1960s, SGS Bateman offers competitive mineral processing plants that reduce risk, shorten project implementation and maximise returns in difficult project locations SGS Bateman modular plants are self contained or are integrated into Modular Plants: Gold Processing

.jpg)

Application Of MineToMill Optimization To The Aggregate

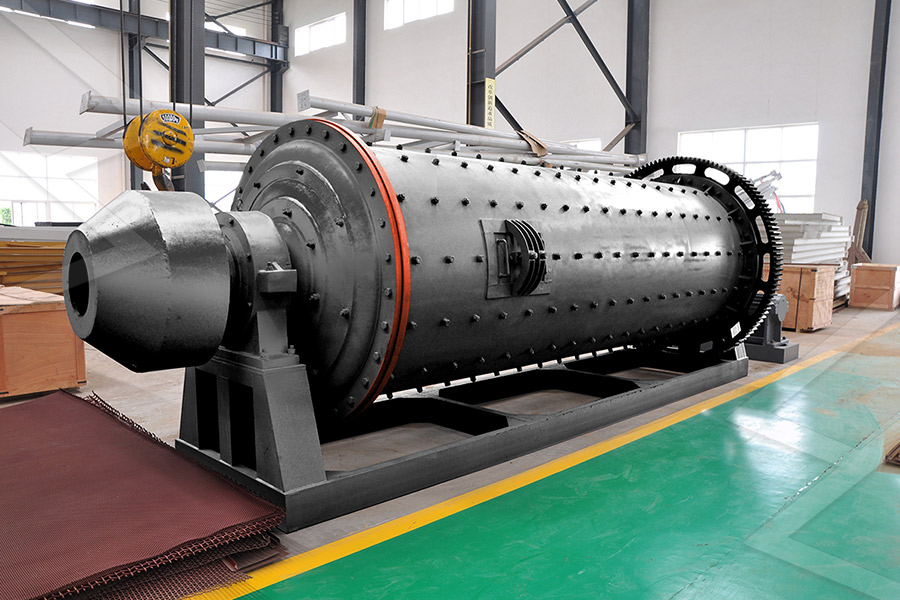

2006年1月1日 — Minetomill optimization is a holistic approach to the optimization of mining and processing operations Developed at the Julius Kruttschnitt Mineral Research Centre, it attempts to minimize energy consumption through the optimization of the particle size reduction process The approach involves sampling and modeling of blasting and 2020年3月1日 — The aim of this research was to conduct an investigation about the early failure occurring near welded joints that connect the slide ring with the head of a large ball mill used in an iron mining plant, and to compare the performance of the steel used in this mill (ASTM A516G60) with three structural steels commonly employed in mechanical Failure analysis of a steel slide ring of a tubular ball mill used in A ball mill consists of various components that work together to facilitate grinding operations The key parts include the following: Mill Shell: The cylindrical shell provides a protective and structural enclosure for the mill It is often made of steel and lined with wearresistant materials to prolong its lifespanBall Mill Grinding Machines: Working Principle, Types, Parts 2022年8月26日 — 至少有几十种形容词说法,而“厂”也可以对应为多种名词,都能想到的有factory和plant,另外mill 也可以表示“工厂”。Factory Plant 英语中的 factory是表示“工厂”的最常用的词语,根源在古罗马的拉丁 Factory、Plant、Mill,大厂是哪种“厂”? 知乎专栏

.jpg)

Modelling and Simulation Techniques Applied for

2024年7月24日 — 3 Comminution Characterisation Rock breakage characteristics are determined by using a dropweight device This is used to break rocks in a range of sizes under a range of2024年1月30日 — Crushed taconite left behind when the mine and processing plant closed under LTV Steel Corp ownership in 2001 — laying off 1,400 workers — has been pulled from the building’s fine ore Massive taconite mills are being removed, recycled from old Erie, LTV plant2023年10月20日 — These include inspecting the mill for any defects, ensuring all the components are in good condition, and verifying that the lubrication system is wellgreased Additionally, it is important to check the grinding media for proper size and weight 1 Mill Inspection Before starting the ball mill, conduct a thorough inspection of the prehensive Guide on Operating a Ball Mill MiningpediaFor flotation mining equipment, APT offers the Trifloat system The TriFloat can be used on sulphide, oxide or silicate minerals; particularly suited to highyield flotation circuits, such as graphite recovery Currently, continuous operation Trifloat plants are available for small scale operations up to 1tph, and laboratory tests on bench Flotation Mining Equipment APT TriFloat — Appropriate

.jpg)

Mill maintenance – 3 simple ways to keep your mill at its best

2017年12月19日 — Insights Blog Mining and metals blog Mill maintenance3 simple ways to keep your mill at its best Mining Metals refining Dec 19, 2017 With the grinding mill critical to a plant’s throughput, it pays to ensure mills receive the necessary care and maintenance Too often mill maintenance is reactive, occurring due to a breakdown The mining operation of mills and plants BY admin April 2nd, 2013 0 Mining Operations using Global Mining Solutions Equipment We are happy to share some photos videos from mining operations around the world Mining plant equipments also important for concrete/aggregates production lines Mining equipments, ball mill, jaw crusher mining operation of mills and plants Mining Quarry PlantAlso the Premier™ mills and Select™ mills come ready to be easily integrated with our mill reline equipment and full mining portfolio providing a onestopshop for your minerals processing needs! Horizontal mill plant units Horizontal Mill Plant Units offer complete support in grinding circuit selection, as well as execution, service Grinding mills for mining and minerals processing 2024年3月21日 — Gouging a mine into the Earth is so 1924 In 2024, scientists are figuring out how to mine with plants, known as phytomining Of the 350,000 known plant species, just 750 are “hyperaccumulators The Feds Are Trying to Get Plants to Mine Metal Through

.jpg)

LOESCHE Wins Order for Coal Mill in Filipino Cement Plant

17 小时之前 — The coal mill for line 3 of the cement plant will ensure the fuel supply and is designed for grinding coal and pet coke with a capacity of 54t/h of mixed coal or 34t/h of pet coke Mining news and indepth feature articles on the latest mining company deals and projects covering trends in mineral exploration with up to date data on the most 2024年4月26日 — The ore is then extracted and transported to the processing plant b Underground Mining: Underground mining is employed when the iron ore deposit is located at significant depths It involves creating underground tunnels and shafts to access the ore Autogenous and SemiAutogenous Mills: In some cases, autogenous (AG) and semi Iron Ore Processing: From Extraction to Manufacturing Mining With over a century of experience, designs and manufactures the most comprehensive line of grinding mills and entire grinding systems for mining companies around the world The comprehensive offering provides reliable and energy efficient technology and solutions across wet, dry, horizontal, and vertical grinding operationsGrinding 2023年8月2日 — Advantages of Hammer Mill 1 Compact structure: Welldesigned and sealed machine body to prevent dust leakage and dust pollution while operating in the workshop 2 Adjustable final size: Gap and discharging particle size of the material is adjustable to suit particular needs 3 Highly automated system: Equipped with an Hammer MillChina Mining Machinery

.jpg)

Leading Gold Mining Growth in Papua New Guinea K92 Mining

K92 Mining Releases Strong 2022 Q2 Financial Results Record Cash Balance, Mine and Mill Throughput; K92 Mining Declares Maiden Inferred Resource of 108 Million oz AuEq or 47 Billion lbs CuEq at the Blue Lake Porphyry; K92 Mining 2022 Second Quarter Financial Results Conference Call Details; K92 Mining Announces Strong Q2 Production Results 2006年9月30日 — MinetoMill optimization is a total systems approach to the reduction of energy and cost in mining and processing Developed at the Julius Krutschnitt Mineral Research Center in Queensland, Australia, the MinetoMill approach attempts to minimize energy consumption through optimization of all steps in the size reduction process The MinetoMill Optimization of Aggregate Production2023年8月28日 — Understanding Coal Mills in Thermal Power Plants: Coal mills are largescale industrial equipment designed to pulverize coal into fine particles suitable for combustion in boilers These mills are typically used in thermal power plants to grind coal to the desired fineness, facilitating efficient combustion and maximizing the generation of Coal Mill in Thermal Power Plant: Enhancing Efficiency and The Anglo American phosphate mine is located in the Brazilian state of Gois and possesses one of Brazil's most important phosphate rock deposits, with the site being the country's second largest producer of phosphate rock concentrate Despite the site having been in operation since 1979, the mining team only started using explosives in 2004 when rocks Fragmentation Optimisation Adopting Mine to Mill for

.jpg)

PITTOPLANT OPTIMISATION AT MORILA GOLD MINE

AngloGold, the operating partner in a joint venture with Randgold Resources and the Government of Mali, own and operate the Morila Gold Mine The open pit gold mining operation is located in Southern Mali, approximately 280 kilometres by road southeast of Bamako, the capital of Mali, West Africa The mined ore is processed through a 2012年6月1日 — on mill dimensions, the type of the mill (overflow or grate discharge), the speed of rotation, the mill loading, the final product size required from a given feed size(PDF) Grinding in Ball Mills: Modeling and Process Control2018年12月15日 — 1 Introduction Mine tailings, the principal solid residuals generated from metalliferous mining activities (Santibáñez et al, 2008), are prone to high concentrations of heavy metals that are potentially toxic to plants and soil biota (Hue, 1995)Vast volumes of these tailings are disposed on mining sites, and depending on the effluent containment Blended pulp mill, forest humus and mine residual material Mine and Mill Industrial Supply Company was incorporated under the name Mulberry Explosives and Supply Company on Octobr 28, 1909 It began as a supply company for the many sawmills and phosphate mining About Mine Mill

Process integration and optimization from minetomill

2024年8月6日 — Process integration and optimization from minetomill WValery,AJankovic,DLaRosa,ADance,SEsen,JColacioppo Minerals Process Technology AsiaPacific 2024年4月11日 — Location: Mount Zynai Industrial Park, Barangay Santa Cruz, Diplahan, Zamboanga Sibugay, Mindanao, Philippines; Coordinates (): 7, 122 (approximate); Background On June 18, 2022, land preparation for the proposed steel plant began at Mount Zynai Industrial Park in Diplahan town of Zamboanga SibugayMount Zynai Integratred Steel Mill and Smelting Plant2022年8月22日 — Throughout the M2M project, sitespecific models of the mine and plant (blast fragmentation, crushing, grinding, gravity separation) were developed and calibrated based on historical data, and (PDF) Mine to Mill Optimisation at Mt Wright ResearchGate2500 South Combee Road Lakeland, FL 33801 Phone: 8002828489, 8636655601 Fax: 8636671907Home Page [minemill]

.jpg)

Newmont Refractory Plant Mill #6 – Western Mining History

6 天之前 — The Newmont Refractory Plant Mill #6 is a mine located in Eureka county, Nevada at an elevation of 6,562 feet About the MRDS Data: All mine locations were obtained from the USGS Mineral Resources Data System The locations and other information in this database have not been verified for accuracy It should be assumed 2017年6月2日 — Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap How it Works: Crushers, Grinding Mills and Pulverizers2018年11月5日 — Minetomill optimisation is a holistic approach to minimising energy and operating costs in mineral processing by optimising all stages within the size reduction process, explains Motion Metrics mine and plant operators must optimise the particle size distribution for each stage of comminution based on an understanding of how each stage Minetomill optimisation Mining Magazine2015年8月8日 — Batch mills Mills which receive a discrete quantity of charge which is milled and then discharged The process is then repeated Continuous mills A mill which can accept a continuous flow of feedstock and hence can operate on a continuous basis Both batch and continuous mills have their relative merits Peripheral and trunnion dischargeMineral processing milling