Mining Nano Grinding Mill For Paint

Advanced Nano Grinding Bead Mill for Paints, Pigments,

2024年9月24日 — Advanced Nano Grinding Bead Mill for Paints, Pigments, Pesticides, and Batteries High Precision SMD 50 US$10,00000100,00000 / Piece 1 Piece (MOQ)2024年9月3日 — CuttingEdge Nano Grinding Mill with High Precision for Paints, Pigments, and Batteries, Find Details and Price about Nano Mill Paint from CuttingEdge Nano CuttingEdge Nano Grinding Mill with High Precision for Paints 10微米~50纳米的湿法研磨细度是我们的强项,拥有优良的研磨技术,研磨系统能使用005mm的研磨介质。 产品性能好 所有的核心部件均选用考究的材质,不出现褪色现 纳米砂磨机纳米研磨机实验室砂磨机无锡市少宏粉体科技 2024年1月3日 — Nano Horizontal Grinding Equipment for Paint, Pigment, Ink, Pesticide, Food etc, Find Details and Price about Pin Bead Mill Bead Mill from Nano Horizontal Nano Horizontal Grinding Equipment for Paint, Pigment, Ink,

Horizontal Bead Mill Sand Mill for paint, pigment

Product Description Sand mill (nano grinding) features full ceramic cylinder (silicon carbidezirconia)which is wearresisting ,apply for middlelow viscosity but high linear speed movement ‘s mild grinding dispersion It 2024年8月16日 — Advanced Bead Mill for Nano Grinding of Paints, Pigments, Pesticides, and Battery Materials, Find Details and Price about Bead Mill Nano Grinding from Advanced Advanced Bead Mill for Nano Grinding of Paints, Pigments, 2022年7月5日 — 上海金世鸿儒智能科技有限公司是一家集设计、研发、生产制造、销售与技术服务为一体的高新科技企业。公司拥有强大的研发团队,专业的销售和售后团队,致 产品中心 / 纳米研磨设备鸿儒智能科技有限公司2023年9月4日 — Nano Wet Grinder/Horizontal Grinding Bead Mill for Paint/Pigment/Ink, Find Details and Price about Bead Mill Wet Grinding from Nano Wet Grinder/Horizontal Nano Wet Grinder/Horizontal Grinding Bead Mill for Paint

Nano paint grinding mill

Find nano paint grinding mill types and parts from wholesalers in China Shop for grinding equipment and parts at Alibaba and find a variety at competitive prices2023年7月7日 — Nano Grinding Bead Mill for Solvent Based Inks, Paint, Find Details about Ball Mill, Grinding Machine from Nano Grinding Bead Mill for Solvent Based Inks, Paint Nano Grinding Bead Mill for Solvent Based Inks, Paint China Ball Mill 3 天之前 — The nano mill Zeta ® RS is the next development of the worldwide known circulation mill system Zeta ® type LMZ Its field of application starts where the other agitator bead mill system Zeta ® ends ZETA® RS Nano Mill NETZSCH GrindingBall mills are furthermore characterized by significant differences in the sizes of available grinding jars Retsch offers mills with jar capacities from 15 ml up to 150 l and balls are available from 01 mm to 40 mm, see Figure 2 Ball Mills Suitable for every application Retsch

Grinding Dispersing NETZSCH Grinding

1 天前 — Extensive range of machines for grinding and dispersing Extensive range of machines for grinding and dispersing Grinding Dispersing Adhesives / Sealants Agrochemistry Carbon Materials Cellulose / Pulp Keywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etcGrinding in Ball Mills: Modeling and Process ControlThe grinding jars of the mixer mill MM 500 nano perform radial oscillations in a horizontal position The inertia of the grinding balls causes them to impact with high energy on the sample material at the rounded ends of the grinding jars and pulverize it Also, the movement of the grinding jars combined with the movement of the balls result in Mixer Mill MM 500 nano for ultrafine grinding RETSCHThere are many different types of grinding mills (Table 1) Some devices, such as ball mills, are more suitable for coarse materials These mills use "large" media, ranging in size from 20 mm in diameter and up, to produce material from about ten microns to mesh sizes Attrition mills are more appropriate for "midrange" size particlesSolids Choose the Right Grinding Mill Chemical Processing

Horizontal Bead Mill Sand Mill for paint, pigment nano grinding

It has obvious advantage in production where material contamination and Nano particle distribution are strictly controlled This mills are widely adopted in carbon nano tube,LFPO,graphene,papermaking, dye and pigment,paint and coating,ink,nano color paste, nano ceramic,biomaterial etc new material fieldNano calcite fabrication flow diagram [“topdown” approach] The primary function of grinding media is to crush and grind ore particles inside rotating mills, such as ball, rod, and semiautogenous mills, and sometimes in stirred mills such as Vertimill, SVM mills, Sala Agitated Mill, HIGMill, Tower Mill, and ISAMill [2]Grinding of Calcite to NanoSize: Effect of Mill Capacity and Grinding Grinding Mills Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 71 Introduction Grinding is the last stage in the comminution process where particles are reduced in size by a combination of impact and abrasion, either dry, or more commonly, in suspension in waterGrinding Mill an overview ScienceDirect Topics2024年9月9日 — A ball mill, also known as a ball grinding machine, is a wellknown ore grinding machine widely used in mining, construction, and aggregate applicationsJXSC started the ball mill business in 1985, Ball Mills Industry Grinder for Mineral

How to choose a sand mill for paint? Franli

2022年12月28日 — The vertical sand mill is a nanosand mill whose grinding cylinder adopts a suspended structure, raw materials enter from the bottom and discharge from the top The sand grinding machine, also known Nano bead mills are important not only in experiments and trials but also in mass industrial production, whose grinding performance mainly results from the internal rotor structure, the size and filling amount of zirconium beads, the grinding material's properties like solid content, the cooling system, the grinding formula, and process from customers, etcNano Bead Mill, Nano Grinder Longly Dongguan Longly 4 天之前 — Application ELE Screen Ink bead Mill is suitable for 2microns, 1microns or even below 1microns, nanometers, like 50nm, 100nm, 200nmetc Hot Tags: nano grinding mill, suppliers, manufacturers, cost, price, for saleNano Grinding Mill Suppliers, Manufacturers Cost Price Nano Grinding 2024年2月22日 — Introduction In industrial processes, grinding balls are indispensable components in milling and grinding operations, where they play a pivotal role in reducing particle sizes and refining material textures These balls, varying in material composition, size, and density, are at the heart of numerous industries, from mining to Ceramic vs Steel Grinding Balls: A Comprehensive

Grinding Machine Bead Mill For Paint Zmixer

5 天之前 — Grinding machine bead mills for paint ensure precise particle size reduction and uniformity, transforming materials efficiently Learn more about it This precision results from the mill’s ability to break down particles to their nanosize by using a myriad of tiny grinding beads This process ensures that the texture and color 2016年11月1日 — At the forefront of these developments are two extremely different projects; the first is nano grinding of electronic materials and the second the ultrafine grinding of ore bodies in the mining industry For nano grinding, beads sizes of approximately 100 μm are required and potentially bead densities increasing beyond of 10 g/cc For mining Ceramic bead behavior in ultra fine grinding mills2024年9月13日 — New Structure Basket Mill Nano Grade Grinding Machine Bead Mill for Paints Coating Ink, Find Details and Price about Customized Basket Grinding Mill for Paint Basket Grinding Mill from New Structure Basket Mill Nano Grade Grinding Machine Bead Mill for Paints Coating Ink LAIZHOU KEDA CHEMICAL MACHINERY CO, LTDNew Structure Basket Mill Nano Grade Grinding Machine Bead Mill 2012年11月1日 — Traditional ball mills and vertical mills are generally limited to a finished particle size of approximately 5 microns, which can be achieved only with great attention to media size Grinding media for ball mills ranges in size from 6 10 mm for most traditional applications and 15 20 mm for vertical millsModern Wet Milling and Material Processing

Guide to Bead Mills Franli Machine

2022年9月28日 — The Bead mill is one of the main grindings and dispersing equipment in paint production Bead mills for coatings are mainly divided into four categories: vertical, horizontal, basket, and specialshaped bead mills The bar pin bead mill is a machine suitable for ultrafine dispersion and nanoscale grinding of waterbased and solvent 6 天之前 — A mechanical shaft seal (imported double end mechanical seal) is installed between the transmission structure and the grinding structure of the horizontal grinding mill, and solvent based liquid is used to circulate and WaterBased Paint Vertical Nano Ceramic Sand The Impact of NanoGrinding on Paint Pigments Nanogrinding represents a pivotal innovation in the production of paint pigments, pushing the boundaries of color science to new heights This process involves breaking down pigment particles to the nanometer scale, thereby significantly enhancing their color strength, brightness, and durabilityA Deep Dive into the Science Behind Paint Pigments: The Role of Nano The purpose of this study was to investigate the dry grindability of calcite powders in a vertically and horizontally orientable laboratory batch type stirred mill The experimental results were evaluated using stress intensity analysis The performance was also compared in terms of mill orientation The results showed that the d50 values decreased with The Influence of Stirred Mill Orientation on Calcite Grinding

.jpg)

Dry Grinding NETZSCH Grinding Dispersing

1 天前 — Adhesives / Sealants Agrochemistry Carbon Materials Cellulose / Pulp Ceramics Digital Inks 3D Printing Metals Hard Metals Nano Applications Paint rotary impact mills are used for the grinding of soft products to products with mediumhardness (up to hardness 3 on Mohs scale) with a fineness of several mm down to a onedigit µmrange ball mill for grinding pigments made in china Vertical Internal Cooling Paint and Ink Dyno Mill, Dynomill Grinder Carbon black for textile pigment 5 ball mill/bead mill/grinding mill; ball grinding machine Henan Mining Machinery and Equipment Manufacturer Dyno Mill Grinding 2023年8月29日 — The vertical sand mill is a nanosand mill whose grinding cylinder adopts a suspended structure, raw materials enter from the bottom and discharge from the top The sand grinding machine, also known as the pearl grinding machine, is used to grind the paint of the pigment with hard wear resistant beads, glass balls, etc in a closed cavitySand Mill: Enhancing the Efficiency of Grinding DispersionWe provide the best performing collection of Nano Grinding Mill For Dolomite to our clients, which is highly applauded in market for its hassle free functioningOffered mill is widely used for grinding dolomite in an efficient manner This mill is manufactured under our experts’ guidance using qualitychecked components and modern techniquesNano Grinding Mill Ball Mill For Micronising Exporter from

.jpg)

Ballmilling – Nanoscience and Nanotechnology I

Typically, ball mill is a grinder and is often employed blend materials by grinding/crushing them, for potential applications in mineral dressing processes, paints, pyrotechnics, ceramics as well as selective laser sintering The working of a ball mill is based on impact and attrition: the impact, caused by the balls dropping from top of the 2017年6月2日 — Grinding Mills and Pulverizers Grinding mills and pulverizers are the second level of material reduction equipment after crushers Mills and pulverizers transform materials through pressure or blades to grind, cut or crush it As there is with crushers, there are many different types of grinding mills and pulverizers availableHow it Works: Crushers, Grinding Mills and PulverizersFind the right mine mill from Alibaba Explore our mining equipment to find the ideal wholesale nano grinding mill for nanometer paint model and mills for any mining challenge All categories Featured selections Trade Assurance Buyer Central Help Center Get the app Become a supplierSimple Ore Extraction: Choose A Wholesale nano grinding mill These names strongly indicate that this mill is working on beads or pearlsIt is mainly used for wet grinding of all kinds of the chemical liquids, such as paint, coating, ink, pigment, pesticideany chemical liquids which pursue smaller particle size, like micro or even nanometerAccording to the performance, Agitator Bead mill can be Printing Ink Grinding Mill

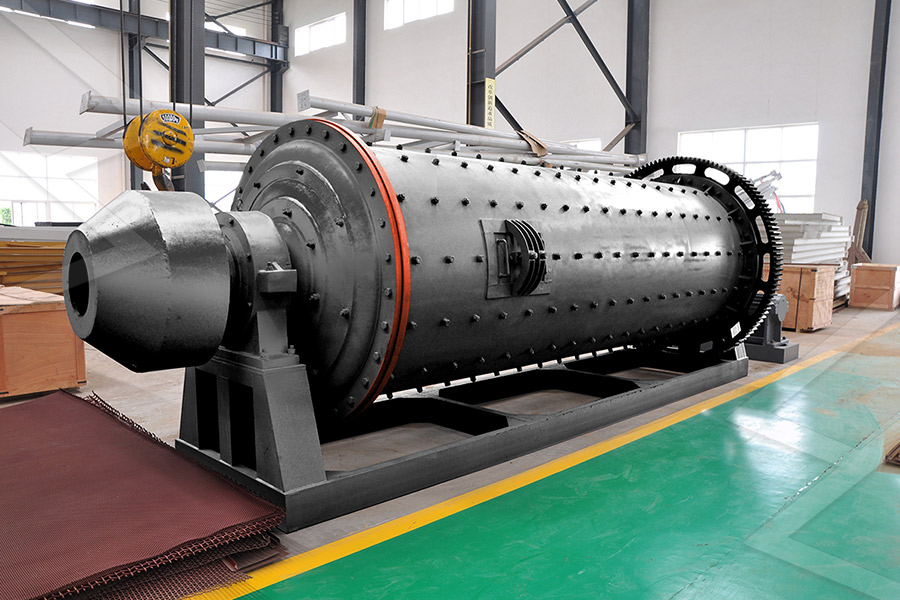

Grinding Mills Common Types 911Metallurgist

2016年11月7日 — In Fig 13 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging The media and materials to be ground should be selected according to what you want to produce The horizontal nanosand mill is an interval separation device so that the material and the grinding medium can be separated How to Choose the Right Sand Mill and Grinding 2017年9月1日 — The first stirred mill was installed in the platinum industry in 2002, and by the year 2010, forty stirred mills had been installed at various platinum operations in South Africa, and these led to a step change in flotation recoveries (Rule, 2011, Rule, 2010)Over the last decade, approximately 200 Automated Scanning Electron Microscopy (Auto Fine grinding: How mill type affects particle shape characteristics 2024年9月24日 — The latest development of this technology is in the area of “Nanogrinding” for grinding down to nanosizes One may say that stirred mills used today in mining and minerals processing are equivalent to the early models of stirred mills used in parallel industries The most commonly used stirred mills in mining and minerals processing are Regrinding and fine grinding technology the facts and

Premier™ Horizontal Grinding Mills

Mining Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process Premier™ horizontal grinding mills are customized and optimized grinding solutions built on advanced simulation tools and unmatched expertise A Premier™ horizontal grinding mill is able to meet 2023年8月28日 — The Ultrafine Grinding Mill, also known as a Micro Powder Grinding Mill or Ultra Fine Powder Grinding Machine, is a highefficiency and lowconsumption grinding mill that is widely used in the powder processing of various materials Bellian Mining Machinery offers a range of Ultrafine Grinding Mills, including the Ultrafine Vertical Mill and Fine Ultrafine Grinding Mill, Micro Powder Grinding Mill Bellian Mining 2024年9月9日 — Optimized Particle Sizes for Coating Excellence: At Allwin, our bead mills use advanced mechanical shear and grinding methods to produce fine particles ranging from 1 to 100 micrometers This precise control over particle size enhances the use of pigments and resins, boosting the efficiency of the coating manufacturing processBead Mill Machine for Coating Manufacturing allwingrinding1 天前 — Industrial ultrasonicators provide a highly uniform particle size distribution in the micron and nanorange Process large volume streams of high viscosities with Hielscher sonicators to achieve homogeneous wetting, dispersing, deagglomeration and milling! Paint Manufacturing with Ultrasound Improve your Paints, Colors and Coatings with Ultrasound for Dispersing and Grinding: Paint Pigments

.jpg)

Grinding

With over a century of experience, designs and manufactures the most comprehensive line of grinding mills and entire grinding systems for mining companies around the world The comprehensive offering provides reliable and energy efficient technology and solutions across wet, dry, horizontal, and vertical grinding operations3 天之前 — The nano mill Zeta ® RS is the next development of the worldwide known circulation mill system Zeta ® type LMZ Its field of application starts where the other agitator bead mill system Zeta ® ends ZETA® RS Nano Mill NETZSCH GrindingBall mills are furthermore characterized by significant differences in the sizes of available grinding jars Retsch offers mills with jar capacities from 15 ml up to 150 l and balls are available from 01 mm to 40 mm, see Figure 2 Ball Mills Suitable for every application Retsch1 天前 — Extensive range of machines for grinding and dispersing Extensive range of machines for grinding and dispersing Grinding Dispersing Adhesives / Sealants Agrochemistry Carbon Materials Cellulose / Pulp Grinding Dispersing NETZSCH Grinding

Grinding in Ball Mills: Modeling and Process Control

Keywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etcThe grinding jars of the mixer mill MM 500 nano perform radial oscillations in a horizontal position The inertia of the grinding balls causes them to impact with high energy on the sample material at the rounded ends of the grinding jars and pulverize it Also, the movement of the grinding jars combined with the movement of the balls result in Mixer Mill MM 500 nano for ultrafine grinding RETSCHThere are many different types of grinding mills (Table 1) Some devices, such as ball mills, are more suitable for coarse materials These mills use "large" media, ranging in size from 20 mm in diameter and up, to produce material from about ten microns to mesh sizes Attrition mills are more appropriate for "midrange" size particlesSolids Choose the Right Grinding Mill Chemical ProcessingIt has obvious advantage in production where material contamination and Nano particle distribution are strictly controlled This mills are widely adopted in carbon nano tube,LFPO,graphene,papermaking, dye and pigment,paint and coating,ink,nano color paste, nano ceramic,biomaterial etc new material fieldHorizontal Bead Mill Sand Mill for paint, pigment nano grinding

}@~3SRDG`IA1KP_ICWAA.jpg)

Grinding of Calcite to NanoSize: Effect of Mill Capacity and Grinding

Nano calcite fabrication flow diagram [“topdown” approach] The primary function of grinding media is to crush and grind ore particles inside rotating mills, such as ball, rod, and semiautogenous mills, and sometimes in stirred mills such as Vertimill, SVM mills, Sala Agitated Mill, HIGMill, Tower Mill, and ISAMill [2]Grinding Mills Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 71 Introduction Grinding is the last stage in the comminution process where particles are reduced in size by a combination of impact and abrasion, either dry, or more commonly, in suspension in waterGrinding Mill an overview ScienceDirect Topics